cairo medium soybean oil production line cost

cairo medium soybean oil production line cost

| Voltage | 380V/50HZ/Triple phase |

| Type | soybean oil production line |

| Structure | Horizontal |

| Weight | 960kg |

| Processing Capacity | 150 tpd |

| Overall dimensions | 2000*720*950mm |

| Power | 22kw |

| Advantage | Simple operation |

| Press Materials | All Oil Seeds |

| After-sales Service | Provide Longlife Technical Support |

| Video put going inspection | provided |

egypt oilseed medium soybean oil production line

due to lower imports, we revise down total soybean consumption in 2015/16 to 1.96 million tons, 6.6% lower than the official usda estimate of 2.087 million tons. the 2016/17 consumption growth forecast is based on the expected recovery in demand growth for soybean meal and soybean oil.

large scale soybean oil production cost report,sourcing resources provides an in-depth cost analysis of soybean oil production, including manufacturing processes, capital investment, operating costs, and financial expenses. our company is one of the leading oil and fat equipment manufacturers in china and a national inspection-free unit. we are committed to introducing new technologies, updating products, and maintaining a leading position in the field. if you have any questions about soybean oil press and other edible oil machinery, please feel free to contact us!

soybean oil processing plant report 2025 establishment cost

our report titled “soybean oil processing plant project report 2025: industry trends, plant setup, machinery, raw materials, investment opportunities, costs and revenues” provides a complete roadmap for establishing a soybean oil processing plant. it covers everything from a comprehensive market overview to micro information such as units.

high quality soybean oil machinery manufacturing business plan machine cost, process,read: best small manufacturing business ideas according to a report by soybean oil press, the global soybean oil market size was valued at approximately $42 billion in 2020. the compound annual growth rate (cagr) is expected to be about 5.1% from 2021 to 2028.

highest operating costs of soybean oil production

utility costs for soybean oil production range from $10,000 to $50,000 per year, depending on usage. maintenance and repair costs: it is essential to keep the equipment running smoothly. the average maintenance cost accounts for about 5-10% of the total equipment cost per year.

best price soybean oil production cost report, by endrusmithrealmedium,soybean oil is one of the most commonly used vegetable oils in the world, known for its versatility in cooking, food processing and industrial applications. its production process is intricate and complex…

how much does a soybean oil production line cost? the processing capacity of the oil production line generally refers to 10-30 tons/day. the main processes for producing soybean oil by pressing are: cleaning-crushing-cooking-pressing-filtering-refining.

low price soybean oil production line overview edible oil press,soybean oil production line is the process of processing soybeans by pressing or leaching to obtain more crude oil, and then refining to obtain edible refined oil. pressed soybean oil has a natural color, aroma and flavor, and retains various nutrients of the raw material compared to leached oil. as an expert in edible oil processing equipment and a complete set of edible oil production lines, we are your reliable choice for soybean oil processing business

how to calculate soybean oil production cost per ton

the daily operating costs involved in pressing the oilseed can make or break a machine processing plant’s profitability. to cope with slim margins and volatile market prices, processors must run their facilities as efficiently and economically as possible which requires a keen understanding of their operating expenses in terms of soybean oil production cost per ton.

hot sale soybean oil production line fully automatic oil pressing equipment,soybean oil production is a complex process involving several stages of extracting and refining oil from soybeans. here is an introduction to the key steps involved in a typical soybean oil production line: 1. soybean preparation and cleaning receiving and storage: soybeans are received and stored in large silos or boxes.

indian soybean oil plant project cost, commercial medium

indian soybean oil plant project cost, commercial medium

commercial medium

collection of commercial medium

soybean oil production line high-efficiency oil press

1. large oil and fat enterprises: suitable for large edible oil processing and production enterprises. 2. small and medium-sized oil presses: provide small and medium-sized production lines to meet customers with different production capacity needs. 3.

high quality soybean oil processing machine for sale,they are simple to operate and have a moderate oil yield. 2.soybean oil solvent extraction machine: these machines use solvents such as hexane to dissolve and extract oil from soybean flakes or residual cakes after pressing. due to their high oil recovery rate, they are more suitable for large-scale industrial production. 3.

efficient soybean oil production line high quality edible

soybean oil production is a complex process involving several stages of extracting and refining oil from soybeans. here is an introduction to the key steps involved in a typical soybean oil production line: 1. soybean preparation and cleaning receiving and storage: soybeans are received and stored in large silos or boxes.

vegetable oil machine soybean oil production line with factory price,1. special grade fragrant soybean oil refining process. this workshop adopts the production process of intermittent refining. according to the type and quality of crude oil, the process parameters are adjusted and different refining methods are selected to produce first-grade oil and third-grade oil.

soybean oil production line soybean oil solvent oil factory

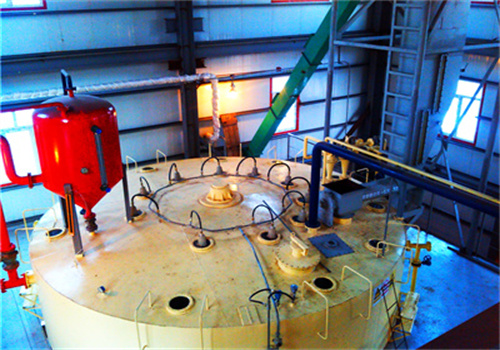

the soybean oil production line includes soybean pretreatment process, soybean pre-pressing process, soybean oil extraction process, and soybean crude oil refining process. our company uses advanced solvent extractors, automatic control systems and other soybean oil equipment to ensure high yield and stable quality of crude oil and refined oil.

high quality soybean oil extractor engineering technology co., ltd. manufacturer,brief overview of soybean oil production line1. advanced soybean oil extraction process, fully considering the characteristics of low cost, energy saving, environmental protection, and heat recovery and reuse. 2. the process can be fully automatically controlled. 3.

unveiling the economics of rbd soybean oil production:

analyzing rbd soybean oil production costs. medium recommended. alexandernguyen. in. upgrade coding. this resume landed a software engineer a $300,000 position at google. 1 page. good

fully automatic soybean oil production line with low cost,our soybean oil production line is designed to meet the international market’s demand for efficient and sustainable production of soybean oil. the composite production line uses the most advanced technology to ensure that each step from soybean cleaning, crushing and extrusion to extraction and refining achieves optimal performance while minimizing energy consumption.

soybean oil production process flow the main process of soybean

the soybean oil production process includes processing soybeans using a pressing method to obtain crude oil, which is then refined into oil. skiptocontentthursday, march 13, 2025

soybean oil production line high quality soybean oil extraction machine,brief overview of soybean oil production line. 1. advanced soybean oil extraction process, fully considering low cost, energy saving, environmental protection, and heat recovery and reuse. 2. the process can be fully automatically controlled. 3.

ultra-simple soybean oil production process design method

the above complete soybean oil production line is suitable for large and medium-sized soybean oil manufacturers with a daily soybean processing capacity of more than 10 tons. when the daily soybean processing volume is less than 10 tons, or the manufacturer’s investment budget is low, a single oil press with high cost performance can be selected.

soybean oil production line automatic oil press

the soybean oil production line is a process of processing soybeans by pressing or leaching to obtain more crude oil, and then refining to obtain edible refined oil. the pressed soybean oil has a natural color, aroma and taste, and compared with the leached oil, it retains various nutrients of the raw materials.