syria cheap palm oil production plant

syria cheap palm oil production plant

| Processing Capacity | 1-30t/d |

| Voltage | 380V/220V |

| Keyword | palm oil extraction machine |

| Power | 30-45kw |

| Overall dimensions | 90*45*85cm |

| Automatic grade | semi-automatic |

| Weight | 1430kg |

| Mechanical Test Report | Provided |

| Related Machine | Sheller/Oil Presser/Oil Refiner/Filling Machine |

| Advantage | Simple operation |

| After-sales Service | Free spare parts, Field installation, commissioning and training |

syria’s energy sector and its impact on stability

syria has the potential to significantly increase its oil and gas production, which could provide energy and government revenues that are vital to its stability and reconstruction. syria had been an oil exporter in the decades before the civil war, and its gas production began to increase on the eve of the war.

large palm oil extractors in syria,syria imports palm oil primarily from the following countries: malaysia ($50 million), turkey ($8.07 million), egypt ($4.89 million), indonesia ($2.48 million), and jordan ($247,000). the fastest growing markets for syrian palm oil imports between 2021 and 2022 are malaysia ($21.9 million), turkey ($7.25 million) and indonesia ($2.12 million).

syria’s energy sector fanack

nevertheless, syria’s oil production averaged over 400,000 barrels per day (bbl/d) between 2008 and 2010, which is relatively high across the mena region. historical production has been declining since its peak in 1996, and with the outbreak of the civil war, production fell sharply to well below consumption.

small syrian oil and gas sector: a complex and uncertain future,syria’s oil production has fallen dramatically since the start of the civil war. in 2010, syria’s oil production was estimated at 385,000 barrels per day (bpd). by 2018, this had plummeted to just 24,000 bpd, largely due to the destruction of oil infrastructure and the loss of control over key oil fields.

syria’s energy crisis – opportunities and implications

since 2011, sanctions have banned the sale and purchase of gas and oil (and related products) from syria, the sale of components, equipment and know-how used in the energy sector, and investment in these sectors in syria, as well as the construction of new power plants and investment in companies engaged in development and production,

high quality keeping warm at all costs: syria’s oil trade and makeshift refineries,as documented in previous open source articles, syria’s oil industry has suffered a severe blow, resulting in severe damage to production facilities, oil spills, and the rise of makeshift refineries in eastern syria, especially in the deir ez-zor region.

syria’s energy sector: a major step towards an economy

damaged oil and gas fields, power plants, and transmission lines have exacerbated a severe power crisis. according to former regime officials, losses in the power sector alone amounted to $40 billion.

factory price palm oil production process: a step-by-step guide,the palm oil production column will go into the details of each process, providing you with the guidance and support you need for your palm oil business. demystifying the palm oil production process steps refining process startup palm oil refinery cost

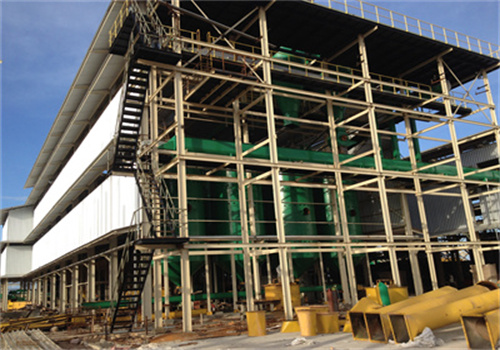

small palm oil processing plant, 120 tons/day production equipment

small palm oil processing plant generally refers to palm oil processing production with a daily production capacity of less than 20 tons. we provide you with two small palm fruit processing solutions! one is a small palm oil processing plant with a daily production capacity of 1~10 tons, and the other is.

low price palm oil production equipment,palm oil refining and fractionation: in order to obtain high-quality palm oil and palm oil for different uses, palm oil refining processes and fractionation processes are required. finally, these refined products are sold in smaller quantities to agents and distributors, who then use palm oil as a base product or a component of goods on supermarket shelves and used in homes.

palm oil no longer the cheapest edible oil in the world

palmoilmagazine, kuala lumpur – palm oil was once known as the world’s most affordable edible oil, but due to declining production, palm oil has lost its low-cost advantagepalmoilmagazine, kuala lumpur – palm oil was once known as the world’s cheapest edible oil, but due to declining production in major producing countries and an oversupply of alternative edible oils, palm oil has lost its low-cost advantage.

high capacity understand palm oil processing plant cost,this is a video of a small palm oil processing plant sent by one of our thai customers. this thai customer was very satisfied with our palm oil processing machinery and after-sales service, and said that he would expand the scale of production in the future. if you

palm oil processing plant design and layout instructions

since then, indonesia and malaysia have become important sources of palm oil production, and their production accounts for about 85% of the global supply. 42 other countries also produce palm oil. palm oil is one of the most common oils and can be used for everything from pizza to lipstick.

best selling cost analysis decoding palm oil grinding plant budget,palm oil refinery machines how many tons of palm oil do you want to produce per day in your palm oil millm larged a small palm oil mill may cost around $70,000 while a large palm oil mill costs $1.

step-by-step guide to setting up a palm oil mill

why is a palm oil mill a highly profitable investmentigh yield per hectare and a lifespan of up to 25-30 years, making it a better agricultural enterprise than other crops. palm oil mills are profitable due to their wide range of uses and high demand for food

start palm oil mill project costing for setup,project cost budget is a very important step before starting palm oil production and is the key to successfully setting up a palm oil processing business. here is how to do a palm oil mill project cost estimate calculation before you start making a business plan.

low cost small palm oil mill with 10 tons per year

end product: red palm oilprocessing process: palm fruit threshing, digestion and sterilization, oil pressing, oil filtering, crude red palm oilproduction capacity: 300 400 kg/hr (5 10 ton/day)occupied area: 15m x 6m x 5mmain equipment includes: palm fruit thresher, cooker (including boiler and 4 baskets), conveyor, palm oil press, oil storage tank (with electric heating system) and tray

the ultimate guide to the palm oil production process,a complex and large-scale palm oil production line installation can achieve up to 24% palm oil extraction rate per bunch. typically, such plants supply international palm oil refineries. the levels may vary between different palm oil processing units.

strategies for success in the palm oil production business

booming palm oil production marketpalm oil is a key ingredient in many of the products we use on a daily basis, from food to cosmetics. the palm oil industry has a bright future and is expected to grow at a cagr of 5.3% from 2021 to 2026. investment

cost efficiency of palm oil production: key factors,start-up costsaverage amount range (usd)land acquisition and site preparation$50,000$500,000production equipment and machinery$100,000$2,000,000extraction and processing facilities$500,000$5,000,000storage and distribution infrastructure