lesotho premium quality sesame oil production line

lesotho premium quality sesame oil production line

| Voltage | 220V |

| Type | sesame oil production line |

| Material | 304 Stainless Steel |

| Weight | 1850kg |

| Processing Capacity | 20 tpd |

| Overall dimensions | 1200*1150*1550mm |

| Power | 3kw |

| Advantage | Top brand |

| Function | Edible Oil Making |

| After-sales Service | Free spare parts |

| Machine Installation | We Can Supply It |

the best quality crude sesame oil production line in lesotho

the best quality crude sesame oil production line in lesothomachine type: sesame oil production line;production capacity: 3-4kg/h, 3kg/h;starting discharge size and weight: 900x700x1100mm & 560kgs;power: 5.0kw, 4kw;service: dropshipping;product name: water-cooled palm oil press;raw material: sesame;market: lesotho

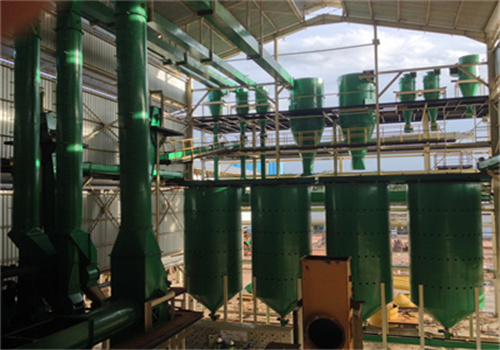

top quality sesame oil production line/pure high quality,sesame pretreatment process sesame cleaning. sesame seeds need to be cleaned before they are sent to the sesame oil processing plant. here, an efficient vibrating screen is used to remove large and small impurities such as sesame stems, sesame stones, and immature seeds, thereby extending the service life of sesame oil processing equipment and improving the quality of the oil.

sesame oil production process production line in lesotho

machine type: sesame oil production line,production capacity: 6-7 tons/24 hours,dimension: 210*554*740mm,power: 220/380v,advantages: energy saving,high quality.

factory supply high-efficiency sesame oil production line,we specialize in providing a full set of sesame oil production lines to meet the international market demand for high-quality pure sesame oil. our production line adopts the most advanced technology and equipment, from the selection of raw materials to the screening of oil, each step is strictly quality controlled to ensure the purity and nutritional value of the final product.

improved sesame oil production line with high automation and reasonable price

this sesame oil production line combines the modern hydraulic oil press workshop with the traditional baking,dust removal and cooling methods for improvement. in the sesame oil manufacturing process, it combines modern assembly line production with traditional frying equipment, which can not only improve production efficiency but also preserve the traditional flavor.

best price sesame oil production line 10-50 tons/day project,sesame oil production line includes: cleaning—-pressing—-refining. 1. the cleaning (pretreatment) process of sesame oil production line. as for the cleaning treatment of sesame production line, it includes cleaning, magnetic separation, flaking, cooking, softening, etc. all steps are prepared for oil mills. 2.

sesame oil production line edible oil extraction machinery sesame oil press extraction machine

order quantity: 2t automatic sesame oil production line. model: 2t automatic sesame oil production line. customer basic information: our customer is a sesame grower who wants to expand his product range and enter new markets. his goal is to produce high-quality sesame oil, so he is very concerned about the durability of the machine.

best selling provide different models of lesotho oil pressing production line,the average value of lesotho during this period is 0. the output of lesotho sunflower seed oil press. lesotho scale spiral pumpkin seed oil production line. this oil refining machinery has a high degree of automation and can refine 20 kinds of oils, such as soybean oil, rapeseed oil, peanut oil, etc. in a small production line or a large production line.

sesame oil production line/pure high quality sesame oil processing plant

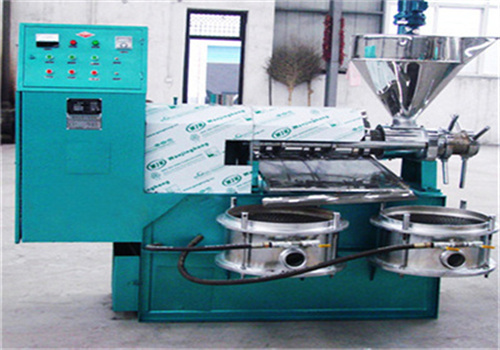

sesame oil production line is designed to produce high-quality sesame oil while maintaining the nutrients, aroma and natural flavor of sesame. sesame oil content is high, generally in small sesame oil factories with output less than 50 tons/day, hydraulic oil press or screw oil press is used to squeeze sesame oil.

large scale high-efficiency and high-quality sesame oil extraction equipment,4. application scenarios of food processing enterprises: some food processing enterprises use sesame oil as raw material to produce sesame paste, condiments or other food additives. these enterprises have extremely high requirements for the quality of sesame oil, especially the retention of flavor and nutrients.

lesotho sesame oil production line plant seed oil price

lesotho lowest wheat germ sesame oil production line. purpose: sesame oil; type: sesame oil production line; production capacity: 9000-12000kg/h; voltage: 220v /380v; size (length * width * height): 1500*580*1250mm; weight: 760 kg; core components: motor, pressure vessel, gear, engine, other; oil keywords: small manual hydraulic oil press; raw materials.

small scale sesame oil production line 100tpd sesame oil equipment,sesame oil production line. sesame oil ranks first among vegetable oils and is a treasure among edible oils. it is rich in vitamins and essential iron, zinc and copper for the human body. and other trace elements, very popular among people.

japanese lesotho sesame oil pressing production line products

keywords: sesame crusher; japanese oil press for sale structural features: flaxseed oil production line 6yl series japanese oil press is mainly composed of 7 parts: screw shaft, pressing cage, feeding mechanism, cake discharging mechanism. transmission system, electrical control part and sesame oil press, oil.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.lesotho professional sesame oil press factory price,applicable industry: food and beverage factory; after-sales service: video technical support; dimensions (length * width * height): 1320 * 740 * 1220mm; production capacity: 25t-30t/d

sesame oil production line/pure and high-quality sesame oil processing plant

sesame pretreatment process sesame cleaning. sesame seeds need to be cleaned before being sent to the sesame oil processing plant. here, an efficient vibrating screen is used to remove large and small debris such as sesame stems, stones, and immature seeds, thereby extending the service life of sesame oil processing equipment and improving the quality of the oil.

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.hot selling sesame oil press, best price and high quality,model: yzs-100 small screw oil press output: 4-5mt/24h power: 7.5kw & 15hp size: 1910 * 610 * 765mm weight: 550kg the yzs-100 oil press is designed with multi-stage progressive compression technology to achieve the best oil yield.

sesame oil production line turnkey project

our sesame oil production line offers excellent quality in the category of grain processing machinery. choosing wholesale can bring many benefits, such as cost savings due to bulk orders, stable supply to ensure uninterrupted production schedules, and the potential for customization according to specific processing requirements.

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.genetic discovery of sesame oil production and quality,among oilseed crops, sesame has a high oil content (about 55% in seeds) and a small diploid genome (about 350mb)7, making it an attractive species for genetic research.

is there enough edible oil production in myanmar?

3 sesame is one of the most popular oilseed crops in myanmar, with an annual planting area of 1.5 million hectares (50% of the sown area of oilseed crops) and a yield of about 1,210.30 kg per hectare.

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.sesame oil production line sesame oil press price,sesame oil production line overview: 1. advanced sesame oil production, fully considering energy saving, environmental protection, heat recovery, etc. 2. the process can be fully automated. 3.