russian 1automatic cottonseed oil production line equipment list

russian 1automatic cottonseed oil production line equipment list

| Voltage | 110v/220v |

| Type | cottonseed oil production line |

| MOQ | 1 set |

| Weight | 530kg |

| Processing Capacity | 3.5 ton/day |

| Overall dimensions | 2400*700*770mm |

| Power | 30-45kw |

| Advantage | High quality |

| Delivery Time | 15days |

| After-sales Service | Field maintenance and repair service |

| Transport Package | Export Fumigation-Free Wooden Box |

150tpd cottonseed oil processing plant, cottonseed oil production line price

cottonseed oil production line 10-1000tpd. qie group was established in 1982 and is a large-scale joint-stock enterprise specializing in the production of edible oil.

top quality cottonseed protein dephenolization equipment low temperature price,cottonseed protein dephenolization equipment low temperature pretreatment, cottonseed oil extraction, cottonseed meal dephenolization plant protein production l, find.

cottonseed oil production line edible oil extraction machine price

brief overview of cottonseed oil production line. 1. the production process of cottonseed oil is advanced, fully considering low cost, energy saving, environmental protection, and heat recovery and reuse. 2. the process can achieve fully automated control. 3.

factory supply cottonseed oil production press line supplier,ys-168 oil press, hy-200 screw press, palm kernel press, cottonseed oil press, oil press, sunflower oil press, soybean oil press 4500-8500 usd/set 1 set (moq)

factory price cottonseed oil production line

cottonseed oil refining can remove peptide impurities, free fatty acids, pigments, odors and other impurities in cottonseed oil, and improve the stability of cottonseed oil. get price product description

best price soybean concentrate protein equipment and production line price,soybean concentrate protein equipment and production line supplier, soybean white flakes, edible oil solvent extraction manufacturer/supplier shandong costa machinery manufacturing co., ltd.

30t/d cottonseed cake and meal oil production line in tanzania

most small and medium-sized cottonseed oil processing plants use screw oil presses to squeeze cottonseed kernels for oil through mechanical pressure to increase oil yield and reduce investment costs. screw oil presses are also used for pre-pressing before solvent extraction. this document discusses cottonseed and its byproducts, cottonseed cake and cottonseed meal. it begins with an overview of the cottonseed production process, including cleaning, delinting, conditioning, and oil extraction. cottonseed cake is the byproduct left after oil extraction and is a common source of protein for ruminants.

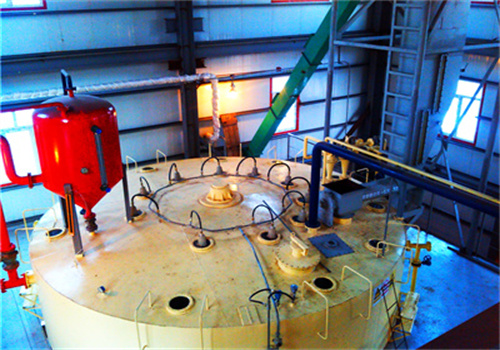

best selling cottonseed oil production line oil processing plant,large cottonseed oil production line includes cottonseed pretreatment and pre-pressing workshop, cottonseed cake solvent extraction workshop and raw cottonseed oil refinery. we customize cottonseed oil production line to meet your special needs.

cottonseed oil full line solution edible oil filling line

over the years, newamstar has made continuous breakthroughs and innovations in the field of edible oil filling and packaging technology. on the one hand, packaging solutions for high-speed blow-fill-seal combined production lines for 5l large bottles and 500ml small bottles have been launched one after another.

large scale cottonseed oil production line cottonseed oil press extraction machine,cottonseed oil degumming generally adopts dehydration process, adding a certain amount of phosphoric acid solution to make the colloidal impurities condense, and then make the colloidal impurities settle and oil separate. there are two types of cottonseed oil deacidification process: chemical deacidification and physical deacidification. the chemical deacidification process is added.

small oil press cottonseed oil processing plant

our cottonseed oil offers superior quality and style in the category of grain processing machinery. choosing wholesale has many advantages, such as cost savings due to bulk ordering, continuous supply to ensure uninterrupted production schedules, and the potential for customization according to specific processing requirements.

small scale factory cottonseed oil production line hot sale cottonseed oil press extraction machine,cottonseed oil production line. cottonseed contains 39-52% shell and 48-61% kernel. shell contains 0.3 to 1% oil. cotton kernel contains 30-35% oil and 35-38% protein. cottonseed contains 0.8% to 1.3% cottonphenol. the traditional production process of cottonseed oil is pre-pressing or pressing. the following is a cottonseed oil production process flow chart.

cottonseed oil processing plant construction cost

cottonseed oil pretreatment equipment, cleaning: remove impurities through magnetic separation, screening and other equipment, crushing, softening, so that the cottonseed is heated evenly.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.new cottonseed oil extractor press for edible oil plant,in any case, high-quality cottonseed oil meal can also add more value to cottonseed oil production. oil machineinery is the top oil press manufacturer in china. we provide a variety of oil pressing equipment for customers who need low-cost and high-quality oil press press. if you are interested in our cottonseed oil.

russian cottonseed oil refining equipment hot sale cottonseed oil press extraction machine

320tpd cottonseed complete set of equipment was successfully delivered. production capacity: 200-380 kg/h; voltage: 220v; dimensions (lxwxh): 2430x1250x2850mm

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.small solvent extraction cottonseed oil equipment price,why buy a small solvent extraction cottonseed oil production plant? high return on investment: low investment cost, high and fast return on investment. easy operation: the entire cottonseed oil extraction tank group is easy to operate. energy saving: this cottonseed oil production line consumes little power. we customize cottonseed oil production line to meet your special needs.

vegetable oil production line cottonseed oil press extraction machine

3, crude oil refining equipment the oil obtained by pressing or solvent leaching is called crude oil. crude oil contains various impurities such as phospholipids, proteins, water, free fatty acids (ffa), pigments, waxes and harmful substances.

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.edible oil production line, edible oil refinery price,the business involves oil pressing machinery, grain and oil engineering design, equipment manufacturing and installation, engineering contracting, technical services, new product research and development, deep processing of oil by-products, etc.

camellia seed oil production line oil plant

camellia oil, also known as tea seed oil, is a high-quality edible oil extracted from the seeds of the camellia plant. we offer complete camellia oil production lines with capacities ranging from 1 ton/day to 500 tons/day. our team provides comprehensive solutions, from plant design to installation, as well as ongoing support to ensure the success of your camellia oil production process.

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.cottonseed oil production line, cottonseed oil production line,main categories: oil pressing; extraction and refining equipment; palm oil machine; soybean oil machine; sunflower oil machine; cottonseed oil machine oil purifier on-time delivery ranked 7th fully customized total construction area (80,553 square meters) total number of trade personnel (40 people) total number of employees (245 people)