canada household pressing cottonseed oil production line

canada household pressing cottonseed oil production line

| Voltage | 440V |

| Type | cottonseed oil production line |

| Features | High Efficiency |

| Weight | 450kg |

| Processing Capacity | 10-1000tpd |

| Overall dimensions | 1950*980*1650mm |

| Power | 37kw |

| Advantage | Low residual |

| Used for | Oil Making Expeller |

| After-sales Service | Technology Supporting |

| Transport Package | Wood |

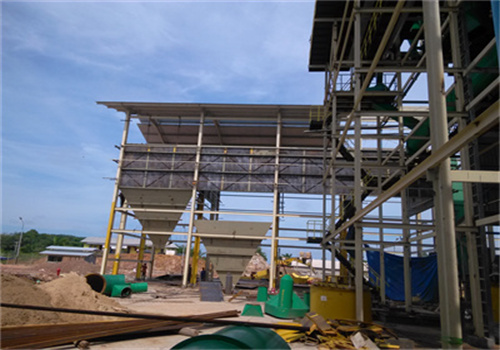

large-scale oil pressing equipment for cottonseed oil production line

the cottonseed oil production process usually uses cottonseed oil pre-pressing machine, cottonseed oil extraction machine and cottonseed oil refiner. cottonseeds can be pressed once and then sent directly to cottonseed oil refineries.

top quality cottonseed oil production line at factory price,oil pressing cottonseed oil pressing is to press cottonseed kernels into flakes to increase the surface area of the oil, destroy its cell structure, shorten the oil output path, and thus speed up the oil output. the pressing efficiency of the oil press and the stability of the equipment are the key to the oil pressing process.

china cottonseed oil production line manufacturers, suppliers price

cottonseed oil production line. cottonseed contains 39-52% shell and 48-61% kernel. the shell contains 0.3 to 1% oil. cottonseed contains 30-35% oil and 35-38% protein. cottonseed contains 0.8% to 1.3% cottonphenol. the traditional production process of cottonseed oil is pre-pressing or pressing. the following is a flow chart of cottonseed oil production line.

factory supply 50 tons/day fully automatic cottonseed oil press extraction machine,the health risks of cottonseed oil: the good, the bad, the greasy. like any good drama, the story of cottonseed oil has its ups and downs. on the positive side, some studies suggest that cottonseed oil may have antioxidant effects and may be beneficial to cardiovascular health. cso is rich in vitamin e compounds, which contribute to its antioxidant properties.

cottonseed oil production line-industry development

the pretreatment equipment adjusts the temperature, moisture and internal organizational structure of cottonseed to make the cottonseed reach a good state before pressing, so as to extract more oil during the pressing process. the cottonseed oil extraction process adopts physical pressing, which has high pressing efficiency.

best price peanuts soybean rapeseed cottonseed sunflower seed use price,peanuts soybean rapeseed cottonseed sunflower seed use edible oil product production line machine, oilseeds: world markets and trade usda foreign www.fas.usda.gov› data and analysis this month’s report includes u.s. and global trade, production, consumption and inventory data, as well as analysis of developments affecting world oilseed trade. covering oilseeds (copra, cottonseed, palm kernel.

cottonseed oil production line edible oil extraction machine price

brief description of cottonseed oil production line. 1. the cottonseed oil production process is advanced, taking into full consideration low cost, energy saving, environmental protection and heat recovery and reuse. 2. the process can be fully automated. 3.

best selling cottonseed oil production line oil processing plant,for cottonseed oil production lines with a daily output of more than 20 tons, solvent extraction is usually used in conjunction with cottonseed oil pre-pressing machines to extract the remaining cottonseed oil. solvent extraction: cottonseed flakes or pressed cakes are subjected to solvent extraction to recover residual oil.

cottonseed oil direct pressing production unit

use a full set of equipment including cleaning, shelling, crushing, tableting, cooking and pressing to optimize the production process of cottonseed oil and efficiently obtain high-quality raw cottonseed oil.

large scale cottonseed oil production line cottonseed oil press extraction machine,the pretreatment equipment adjusts the temperature, moisture and internal organizational structure of cottonseed to make the cottonseed reach a good state before pressing, which is convenient for extracting more oil during the pressing process. the cottonseed oil pressing process adopts physical pressing, which has high pressing efficiency.

cottonseed oil equipment production line

find wholesale cottonseed oil equipment production line to help you provide pure, chemical-free oil. visit alibaba.com to choose from a wide range of oil presses to meet your needs.

small scale cottonseed oil press oil refinery,2. cottonseed oil pre-pressing → cottonseed oil extraction → cottonseed oil refining. usually for situations where the daily input capacity exceeds 20 tons, it is best to use the second cottonseed oil processing plant processing method, which is more cost-effective. here we will introduce you to the second method. cottonseed oil processing plant starts with pre-pressing.

cottonseed oil extraction plant

for production lines with a daily output of more than 20 tons, solvent extraction is usually used in conjunction with cottonseed oil pre-pressing machines to extract part of the oil. the machine has a large output, low cake residual oil rate, and is easy to penetrate with solvents.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.cottonseed oil cake pressing machinery oil processing plant,the advantages and disadvantages of cottonseed oil cake pressing machinery for small-scale cottonseed oil production, cottonseed oil cake pressing machinery plays a big role. every product has its ups and downs. it has parts with high yield and parts with low yield.

cottonseed oil press professional price supplier

the entire cottonseed oil pressing production line consists of three workshops: cottonseed pretreatment workshop, cottonseed leaching workshop and cottonseed refining workshop. this small set of equipment has a small footprint, low investment, wide range of uses, and labor saving. it is the best choice for small oil pressing enterprises! m

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.cottonseed oil production line – great global solutions co., ltd,the pretreatment steps of cottonseed oil production line mainly include cleaning, shelling and crushing, cooking and pressing. cottonseed oil refinery can remove peptide-soluble impurities, free fatty acids, pigments, odors and other impurities in cottonseed oil, and improve the stability of cottonseed oil. 1.

fully automatic cottonseed oil production line cottonseed oil press extraction machine

6yl-125 sunflower seed screw oil press; 6yl-121 sesame screw oil press; 6yl-128 shea butter tea seed oil press; 6yl-360 screw oil press; 6yl-131 soybean screw oil press; 6yl-170 avocado screw oil press; 6yl-200 chia seed castor oil press; hydraulic oil press. hydraulic oil model.

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.cottonseed oil production line cottonseed oil press extraction machine,pre-pressing and extraction method to produce cottonseed oil and crude cottonseed oil refining. cottonseed oil production process: shelling → cleaning → magnetic separation → shelling → kernel separation → embryo rolling → puffing steaming → pre-pressing → leaching → refining → defatting fractionation.

cottonseed oil production line edible oil production line price

small equipment can meet the delivery conditions within 30 days, equipment with a daily output of 10-30 tons can meet the delivery conditions within 45 days, equipment with a daily output of 30-100 tons can meet the delivery conditions within 60 days, and equipment above 100 tons can be completed on time as stipulated in the contract.

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.