competitive small cottonseed oil production line in delhi

competitive small cottonseed oil production line in delhi

| Voltage | 220v 50hz |

| Type | cottonseed oil production line |

| Color | can be customized |

| Weight | 1780kg |

| Processing Capacity | 5-30t/d |

| Overall dimensions | 2020*1315*1570mm |

| Power | 15kw |

| Advantage | Top brand |

| Press Series | Oil Production Line |

| After-sales Service | 7*24 Hours Online Service |

| Transport Package | Wooden Case Packaging |

small cottonseed oil production line large oil pressing equipment

it is actually very important to conduct a complete market research on cottonseed oil. however, for cottonseed oil, the global demand for cottonseed oil is much greater than the global supply of cottonseed oil. therefore, it is definitely profitable to build a complete cottonseed oil processing plant. make a comprehensive business plan

top quality life cycle assessment of cottonseed oil tro india,2.2 world cottonseed oil production cottonseed production is generally consistent with cotton production, but there may be some slight differences due to the different ratios of cotton lint to seeds in different countries. this can be affected by the planting variety and climatic conditions. cottonseed oil production in various countries can

delhi cottonseed oil and press extraction machine

applicable industries: food and beverage stores; after-sales service: overseas service machinery; size (length * width * height): 1910 * 610 * 765mm; production capacity: 100-200t/d

factory supply factory cottonseed oil production line high quality oil press extraction machine,cottonseed oil production line. cottonseed contains 39-52% shell and 48-61% kernel. the shell contains 0.3 to 1% oil. cottonseed contains 30-35% oil and 35-38% protein. cottonseed contains 0.8% to 1.3% cottonpol. the traditional production process of cottonseed oil is pre-pressing or pressing. the following is a cottonseed oil refining process flow chart.

delhi 10-200td cottonseed oil pressing production line

soybean oil production line is the process of processing soybeans through pressing or leaching to obtain more crude oil, and then refining to obtain edible refined oil. pressed soybean oil has natural color, aroma and flavor, and compared with leached oil, it retains various nutrients of the raw materials. .

best price factory price cottonseed oil production line,cottonseed oil refining can remove peptide impurities, free fatty acids, pigments, odors and other impurities in cottonseed oil and improve the stability of cottonseed oil. get price product description

small oil production line for various oilseeds and nuts

advanced software and a perfect working environment enhance our equipment to achieve a more scientific and professional workflow. manufacturing our own machinery allows us to control the supply of advanced oil production equipment, which improves predictability and compatibility. our small oil production line can handle a variety of plants.

best selling soybean oil production line – efficient and sustainable,small and medium-sized oil mills: provide small and medium-sized production lines to meet customers with different production capacity needs. 3.agricultural product processing enterprises: suitable for enterprises processing soybeans and other oilseeds in agricultural product producing areas to increase the value chain extension.

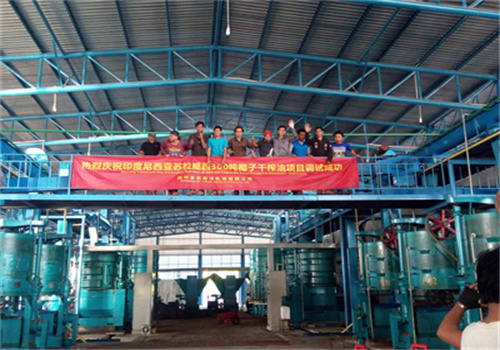

10tpd cottonseed oil refining line in afghanistan

through constant communication and confirmation, he was satisfied with our proposed production plan. finally, he purchased a 10tpd cottonseed oil refining and fractionation production line and packaging and filling machines to equip his cottonseed oil pressing plant into a complete cottonseed oil production plant, which includes cottonseed oil pressing, cottonseed oil refining and cottonseed oil.

large scale set up your own small oil pressing line at the lowest cost,5tpd mini edible oil production line. we design and build small oil pressing lines that can process cottonseed, palm kernel, coconut, peanut, almond, cactus seed, rapeseed, mustard seed, flax seed, sunflower seed and many other oil mill plants and nuts.

cottonseed oil production press line supplier

ys-168 oil press, hy-200 screw press, palm kernel press, cottonseed oil press, oil press, sunflower oil press, soybean press4500-8500 usd/set1 set (moq)

small scale 10tpd cottonseed oil refining production line in delhi, best price,applicable industries: retail; after-sales service: video technical support, online support; dimensions (l*w*h): 1900*670*830mm; production capacity: 10t/d-1000t/d

complete cottonseed oil production line. cottonseed oil price

for large cottonseed oil production lines with a capacity of more than 30 tpd, solvent extraction is usually combined with cottonseed oil pre-pressing to maximize the oil yield. large cottonseed oil production lines include cottonseed pretreatment and pre-pressing workshops, and cottonseed cake solvent extraction workshops.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.indian cottonseed oil manufacturers companies – top 20 out of 70 companies,list of best cottonseed oil companies in india. the cottonseed oil processing process contains several steps, which can be simply divided into: cleaning, dehulling, flaking, softening, pressing, filtering or refining. we are a delhi-based business intelligence company committed to building world-class business intelligence products that help you improve business efficiency, productivity, and scalability.

10-20t/d edible oil production line

our company specializes in customizing small capacity edible oil production lines. 10-20t/d edible oil production line is suitable for home workshops and small oil mills. we provide a variety of machines for oilseed pretreatment, oilseed pressing, crude oil refining and finished oil packaging.

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.cottonseed oil production line cottonseed oil press extraction machine,finally, there is a special process for cottonseed oil refining – cottonseed oil fractionation process. it is the separation of solids and liquids in cottonseed at a specific temperature. similar to the palm oil fractionation process, through cooling, crystallization and filtration, two parts can be obtained: cottonseed oil olein and cottonseed oil stearin.

cottonseed oil press oil extraction refinery

there are two solutions for cottonseed oil production: 1. cottonseed oil press → cottonseed oil refinery 2. cottonseed oil pre-pressing → cottonseed oil extraction → cottonseed oil refinery. usually, for input capacity exceeding 20 tons per day, the second cottonseed oil mill processing method is better and less costly.

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.palm oil mill production line qie group,batch type is ideal for small-scale production (1-20tpd), while medium-to-large production lines (20-50tpd) and fully continuous refining lines (50-600tpd) are ideal. this refining process is suitable for refining soybean oil, rapeseed oil, sunflower oil, palm oil, cottonseed oil, etc. qie group is a large joint venture.

cottonseed oil market size, share, analysis and trends, 2032

global cottonseed oil market size (2024-2032) the global cottonseed oil market size is expected to reach usd 5.51 billion in 2024, growing at a cagr of 3.75% from 2024 to 2032, reaching usd 7.4 billion by 2032. cottonseed oil is a vegetable oil extracted from cottonseed (gossypium).

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.cottonseed oil production line edible oil press price,the cottonseed oil production process is advanced, fully considering low cost, energy saving, environmental protection, and heat recovery and reuse. the process can be fully automatically controlled. high-performance, high-quality equipment coupled with overseas door-to-door delivery and installation services ensure long-term and stable operation of the equipment.