zimbabwe cottonseed double oil production line cost

zimbabwe cottonseed double oil production line cost

| Voltage | 110v/220v |

| Type | cottonseed oil production line |

| Material | carbon steel and stainless steel |

| Weight | 1042kg |

| Processing Capacity | 20-150t/d |

| Overall dimensions | 2200*720*1030mm |

| Power | 37kw |

| Advantage | Top brand |

| Press Materials | All Oil Seeds |

| After-sales Service | Service Machinery Overseas |

| Machine Mainly | Matched with The Whole Oil Press Line |

cotton large oil production line costs

for the period 2012 to 2022. the highest production was in the 2012 marketing year at 350,703 tonnes. thereafter, production declined sharply, falling to 28,598 tonnes in 2016. cotton production has been on a downward trend as shown by the blue dashed trend line. some of the challenges that affected production during this period include, but are not limited to

top quality economic analysis of factors affecting the price of cotton production,economic analysis of production costs shows that labour alone accounts for 50% of the variable costs of cotton production per hectare. regression analysis showed that the best fitting model was the log-log function; its coefficient of determination (r 2) was 0.61.

growth in seed cotton production in zimbabwe united nations conference on trade and development

uzbekistan 4.4% cotton seed procurement price is set and guaranteed by the state. turkey 3.1% cotton seed procurement price is subsidized by the state. greece 1.2% cotton seed procurement price is guaranteed by the eu (partial equalization) australia 1.1% cotton fiber market price turkmenistan 1.0% cotton seed procurement price is set and guaranteed by the government.

factory supply dileep kumar chaurasiya cottonseed processing plant prices,cottonseed processing plant and oil mill manager · cangrow trading pvt.ltd. harare zimbabwe · harare · 10 contacts on. view dileep kumar chaurasiya’s profile on the professional community with 1 billion members.

zimbabwe needs 600 000 hectares of cotton for edible oil production zimbabwe situation

processing of seed cotton from hybrid seeds will produce about 603 200 tonnes of lint from which about 120 640 tonnes of cooking cotton can be produced. as the country requires about 12 000 tonnes of edible oil per month, this production will ensure that the country is self-sufficient in edible oil from cottonseed alone for 10 months.

best price small cottonseed oil production line large oil pressing equipment,it is essential to conduct a comprehensive market research on cottonseed oil. but for cottonseed oil, the global demand for cottonseed oil is much greater than the global supply of cottonseed oil. therefore, it is absolutely profitable to set up a complete cottonseed oil processing plant. make a comprehensive business plan

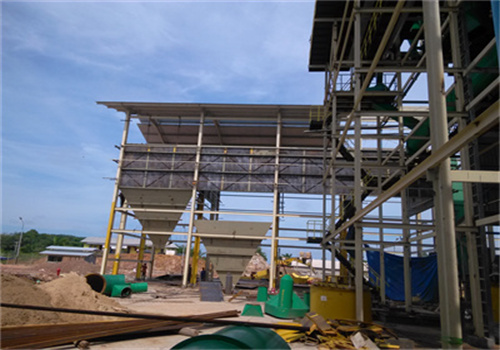

cotton seed oil press solvent extraction refining line in zimbabwe

the cotton industry in zimbabweafrica regional working paper series no. 122 february 2009 abstract this country study is a background paper to

best selling factors affecting seed cotton price marketing decisions,a sample of 1080 cotton farmers representatives were randomly selected from these provinces, and the market participation and intensity were assessed using a double hurdle model, guided by a probit model.

zimbabwe cottonseed oil market report 2025 prices

cottonseed oil exports zimbabwe exports. in 2018, zimbabwe exported x tonnes of cottonseed oil, an increase of x% over the previous year. overall, cottonseed oil exports continue to show moderate growth. the most prominent growth rate was in 2011, which increased by x% year-on-year. that year, cottonseed.

large scale cottonseed oil processing plant report 2025: setup cost,the cottonseed oil processing project report details the project economics, including capital investment, project funding, operating expenses, revenue and expense forecasts, fixed and variable costs, direct and indirect costs, expected roi and net present value (npv), profit and loss statement, financial analysis, etc.

how to choose cottonseed oil press machine manufacturer price

the indicative price of cottonseed oil press machine is now required, including spare parts required for two years of operation. the price and details of 5tpd press workshop equipment are included in the email attachment.

small scale setting up a large scale cottonseed oil production line in zimbabwe,ultimately sunflower production and processing oilseed production is mainly focused on groundnut (40%), sunflower (36%), sesame (15%), cotton (8%) and palm oil

2024 cottonseed oil manufacturing plant report: setup and cost

2025 cottonseed oil manufacturing plant project report. report contents: industry analysis (market performance, market segments, price analysis, outlook), detailed process flow (product overview, unit operations, raw materials, quality assurance), requirements and costs (machinery, raw materials, packaging, transportation, utilities, human resources), project economics (capital investment.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.cotton production and consumption in zimbabwe,production costs. the zimbabwean government has pledged to provide free inputs to cotton farmers for the third consecutive year in 2017/18. good local cottonseed prices will also have a positive impact on national cotton production. cottonseed is the main raw material for the production of edible oil and livestock feed, and local demand for cottonseed is strong.

cottonseed oil production line oil plant

for large-scale cottonseed oil production lines with a capacity of more than 30 tpd, solvent extraction is usually used in combination with cottonseed oil pre-pressing to maximize oil production. large-scale cottonseed oil production lines include cottonseed pretreatment and pre-pressing workshops, and cottonseed cake solvent extraction workshops.

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.cottonseed oil manufacturing project report,cottonseed oil manufacturing project report profitability (before income tax)annual gross profit: rs. 5,34,700 sales profit percentage: 12.51%; break-even analysis; annual sales: rs. 42,75,000; annual variable cost: rs. 30,36,000; cottonseed oil manufacturing project report break-even point calculation

cotton and its by-products united nations conference on trade and development

in terms of cottonseed value, a zimbabwean oil miller estimated that cottonseed meal accounts for the majority of the total cottonseed value, accounting for about 44%, followed by edible oil, accounting for about 18%, cotton hulls (9%) and cotton lint (7%).

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.survey and analysis of cotton by-products in zimbabwe united nations conference on trade and development,– oil (oil accounts for 18% of seed value)– cottonseed meal (44% of seed value)– cotton lint– cotton hulls– gum used to produce lecithin for margarine production– export • in zimbabwe, cottonseed has commercial value in seed propagation, feed manufacturing, oil pressing and export; • one ton of cottonseed can produce 200 kg of oil, 500 kg of

what is the production process of cottonseed oil?

cottonseed oil extraction involves a series of oil-making processes and professional oil-making machinery. regardless of the size of your cottonseed oil processing plant, basic production processes are required to produce high-quality cottonseed oil. the detailed cottonseed oil production process is as follows. cleaning: remove organic impurities (stems, leaves, etc.)

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.zimbabwe cottonseed oil plant project report high quality oil press extraction machine,name: edible oil plant; residual oil in meal: less than 1%; crude oil moisture and volatile matter: less than 0.30%; consumption: low; oil grade: grade 1, 2, 3. after-sales service: overseas engineering service; the report also covers a detailed analysis of the project economics of setting up a cottonseed oil processing plant.