factory purchase argentina cottonseed oil production line design

factory purchase argentina cottonseed oil production line design

| Voltage | 440V |

| Type | cottonseed oil production line |

| Color | can be customized |

| Weight | 1500kg |

| Processing Capacity | 10-25t/d |

| Overall dimensions | 1000*538*1050mm |

| Power | 11-15kw |

| Advantage | Multifunctional |

| Press Series | Oil Production Line |

| After-sales Service | Free spare parts, Video technical support |

| Machine Installation | We Can Supply It |

china cottonseed oil production line manufacturers, suppliers price

cottonseed oil production line. cottonseed contains 39-52% shell and 48-61% kernel. the shell contains 0.3% to 1% oil. cottonseed contains 30-35% oil and 35-38% protein.

top quality china sesame oil production line manufacturer, supplier price,we are a professional sesame oil production line manufacturer and supplier in china, committed to providing high-quality products. we warmly welcome you to wholesale bulk sesame oil production line from our factory. for price consultation, please contact us.

factory direct cottonseed soybean palm sunflower seed price

factory direct cottonseed soybean palm sunflower seed mustard oil press production line, find complete details about factory direct cottonseed soybean.

factory supply china cottonseed oil press manufacturer price,8. clarification and filtration of oil by cottonseed oil press: the squeezed oil has more impurities, so it should be cooled quickly and filtered after standing for a while to prevent the oil from turning black and increasing refining losses. hot tags: cottonseed oil press, china, manufacturers, suppliers, factory, buy, cheap,

china cottonseed oil production line manufacturers, suppliers price

cottonseed oil production line. cottonseed accounts for about 65% of the weight of cottonseed. when delinting cottonseed, the lint yield should be increased as much as possible and the crushing rate should be reduced.

best price how does the edible oil processing plant produce cottonseed oil?,cottonseed oil solvent extraction plant. the cottonseed oil solvent extraction plant uses n-hexane to extract oil from cottonseed cake, and the final residual oil rate can be less than 1%. the oil you get is also crude cottonseed oil, which must be sent to the edible oil refinery to be refined into finished oil. the above is.

china cottonseed oil extraction machine manufacturer price

“cottonseed oil extraction machine” is a “green and healthy edible oil” refined by physical pressing process. the pressing process retains the nutrients in the oil, and no chemical solvents are added, ensuring that the oil is safe, pure, nutritious and delicious, in line with human needs, and suitable for long-term consumption.

best selling china oil production line manufacturers, suppliers, ex-factory price,moringa seed oil production line. moringa seed oil production line includes: material pretreatment / pressing / refining / packaging / feeding 1. basic information of moringa seed oil 1. unrefined moringa seed oil is dark yellow with.

china olive oil production line manufacturer, supplier price

olive oil production line. olive oil press olive oil is directly cold-pressed from fresh olive fruits without heating and chemical treatment, retaining natural nutrients, so olive oil is considered to be the most suitable oil for human nutrition among the oils discovered so far.

large scale micro/small solvent extraction equipment price for cottonseed oil,why buy a small solvent extraction plant to produce cottonseed oil? high roi: low investment cost, high and fast roi. easy to operate: the entire tank group for cottonseed oil extraction is easy to operate. energy saving: this cottonseed oil production line consumes little electricity. for example, 10tpd.

cottonseed oil production line ex-factory price commercial oil press extraction machine

find manufacturers, suppliers and exporters of cottonseed oil production line in china here. get the contact information and address of companies that manufacture and supply press solvent extraction production line

small scale factory cottonseed oil production line high quality oil press extraction machine,cottonseed oil production line. cottonseed contains 39-52% hull and 48-61% kernel. the hull contains 0.3% to 1% oil. cottonseed contains 30-35% oil and 35-38% protein. cottonseed contains 0.8% to 1.3% cottonpol. the traditional cottonseed oil production process is pre-pressing or pressing. the following is a cottonseed oil production flow chart.

cottonseed oil production line oil plant

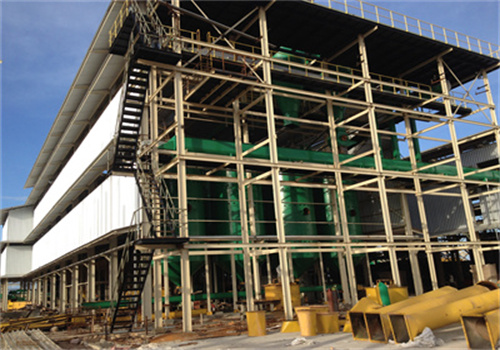

for large cottonseed oil production lines with an output of more than 30 tpd, solvent extraction is usually combined with cottonseed oil pre-pressing to maximize the oil yield. large cottonseed oil production lines include cottonseed pretreatment and pre-pressing workshops, cottonseed cake solvent extraction workshops.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.cottonseed oil plant manufacturers, suppliers, factory prices,cottonseed oil plant is very suitable for extracting and producing oil from any kind of oilseeds, such as groundnut/peanut, sesame, sunflower seeds, cottonseed, rice bran, rapeseed, soybean and palm kernel, etc. as a cottonseed oil plant manufacturer, we can provide the entire production line or part of the cottonseed oil plant, with a general capacity ranging from 10tpd to 1000tpd.

oil pressing plant oil pressing plant 10-500 tpd

equipment: agico the cost of an oil press is greatly affected by the output and process design. the price of a small oil press is about $20,000 to $30,000. the price of a small oil press plant is about $20,000 to $30,000. to run an oil press plant with a daily output of 50 tons, it takes about $60,000 in equipment investment.

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.start your own small solvent-based cottonseed oil plant at factory direct prices,the cottonseed oil cake produced by the cottonseed oil processing plant using mechanical pressing technology can reach an oil content of 8%~13%. we provide cost-effective solutions for cottonseed oil production companies. investors who are interested in investing in cottonseed oil processing are welcome. vegetable oil pressing plant, produces a large amount of oil cakes every day.

small oil extraction equipment layout design

nowadays, people have a growing demand for high-quality edible oil, so starting a small scale edible oil production plant is a good business investment for farmers, young entrepreneurs with limited funds, businessmen who want to try their hand in the edible oil industry, etc., because the cost of an edible oil production plant is much lower compared to large-scale plants.

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.automatic 200 tpd cottonseed oil processing plant installation price,oil pressing. we use only the latest technology to ensure the highest oil return; pre-pressing and solvent extraction processes obtain more oil. this practice is quite common in commercial cottonseed oil production in an attempt to increase overall yield. oil filtration

cottonseed oil production line cottonseed oil press extraction machine

finally, there is a special process for cottonseed oil refining – cottonseed oil fractionation process. it is to separate the solid and liquid in cottonseed at a specific temperature. similar to the palm oil fractionation process, through cooling, crystallization and filtration, two parts can be obtained: cottonseed oil olein and cottonseed oil stearin.

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.cottonseed oil production line edible oil press price,the cottonseed oil production process is advanced, fully considering low cost, energy saving and environmental protection, and heat recovery and reuse. the process can be fully automated and controlled. high-performance, high-quality equipment plus overseas door-to-door installation services ensure long-term and stable operation of the equipment.