cairo how to build a cottonseed oil production line

cairo how to build a cottonseed oil production line

| Voltage | 380V/50HZ/3 phase |

| Type | cottonseed oil production line |

| Material | stainless steel |

| Weight | 950kg |

| Processing Capacity | 80-130kg/H |

| Overall dimensions | 1020*920*880mm |

| Power | 2.2-18.5kw |

| Advantage | High output |

| Operation Manual | Can Be Provided |

| After-sales Service | Free spare parts |

| Spaer Parts Available | Long Time Supply Spare Parts |

building cairo

there are many ways to build cairo. almost unlimited, in fact. below is a list of build “recipes”. choose the recipe that works best for you and have fun building cairo. end-to-end builds for mac os x. end-to-end builds for win32. building cairo with jhbuild on win32

top quality china cottonseed oil production line manufacturer, supplier price,cottonseed oil production line. cottonseed contains 39-52% shell and 48-61% kernel. the shell contains 0.3 to 1% oil. cottonseed contains 30-35% oil and 35-38% protein. cottonseed contains 0.8% to 1.3% cottonpol. the traditional production process of cottonseed oil is pre-pressing or pressing. the following is a flow chart of cottonseed oil.

cottonseed oil production line cottonseed oil press extraction machine

cottonseed oil degumming is generally used for dehydration processes. add a certain amount of phosphoric acid solution to coagulate the colloidal impurities, then sink the colloidal impurities and separate the oil. there are two types of cottonseed oil deacidification processes: chemical and physical. the chemical deacidification process is added.

factory supply edible oil extraction machinery: how to establish cottonseed price,edible oil extraction machinery tags. 1tph cottonseed oil refining project (1); 200kg/h cottonseed oil press (1); 2023 palm oil refinery shipped to tanzania (1); 20tpd sunflower oil processing machine fob price (1)

factory cottonseed oil production line high quality oil press extraction machine

cottonseed oil production line. cottonseed contains 39-52% shell and 48-61% kernel. the shell contains 0.3 to 1% oil. cottonseed contains 30-35% oil and 35-38% protein. cottonseed contains 0.8% to 1.3% cottonpol. the traditional production process of cottonseed oil is pre-pressing or pressing. the following is a process flow chart of cottonseed oil production.

best price ex-factory cottonseed oil production line,the cottonseed oil production process usually uses cottonseed oil pre-pressing machine, cottonseed oil extraction machine and cottonseed oil refinery. cottonseed can be pressed once and then sent directly to the cottonseed oil refinery.

china cottonseed oil production line manufacturer, supplier price

cottonseed oil production line. cottonseed contains 39-52% shell and 48-61% kernel. the shell contains 0.3 to 1% oil. cottonseed contains 30-35% oil and 35-38% protein. cottonseed contains 0.8% to 1.3% cottonpol. the traditional production process of cottonseed oil is pre-pressing or pressing. the following is a process flow chart of cottonseed oil production.

best selling cottonseed oil: extraction technology price review,cottonseed oil (cs-o) has received more attention due to its high fiber content and stability to auto-oxidation. cs-o has won a good reputation in the global edible oil market because.

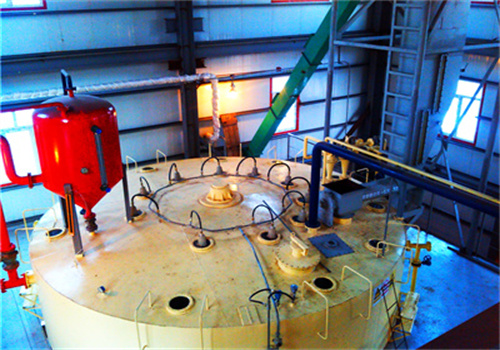

200 tons/day cottonseed oil pressing production line

the good, the bad and the greasy: the health effects of cottonseed oil. like any good drama, the story of cottonseed oil has its ups and downs. on the positive side, some studies have shown that cottonseed oil may have antioxidant and cardiovascular benefits. cso is rich in vitamin e compounds, which contribute significantly to its antioxidants.

large scale how to set up a mini cottonseed oil mill plant? mini price,read more about cottonseed oil solvent extraction method>>. set up a cottonseed oil mill plant. this small oil press is not only suitable for cottonseed, but also ideal for extracting oil from many other oilseeds and nuts, such as mustard seeds, peanuts, flax seeds, linseeds, poppy seeds, peanuts, sesame seeds, rapeseed, sunflower seeds, soybeans, etc.

how does the edible oil processing plant make cottonseed oil?

cottonseed oil solvent extraction plant. the cottonseed oil solvent extraction plant uses n-hexane to extract oil from cottonseed cake, and the final residual oil rate can be less than 1%. the oil you get is also crude cottonseed oil, which must be sent to the edible oil refinery to be refined into product oil. the above is.

small scale want to build a cottonseed oil extraction plant from a to z?,cottonseed and cottonseed oil. cottonseed is a rich source of oil and protein. cottonseed oil is an important heart-healthy oil because of its high content of unsaturated fatty acids. cotton is a cash crop for more than 20 million farmers in developing countries in asia and africa. it is mainly grown to meet the basic requirements of cotton fabrics.

cottonseed protein production line cottonseed oil press extraction machine

refining cottonseed oil using a mixed oil refining process can help remove gossypol in the process, reduce refining losses, improve oil color, improve product quality, simplify oil processing, and have better results than other refining processes. this is more suitable for the specific oils of refining cottonseed oil.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.cottonseed oil processing machine to establish a complete oil plant,just consider factors such as cottonseed quality, processing capacity, market demand for refined oil, investment budget, and then choose the appropriate cottonseed oil production line production process. different cottonseed oil production equipment can be selected and configured according to the budget cost.

how to build a small edible oil production line? oil pressing plant

with the increasing demand for edible oil leading to rising prices, many people have recently started making edible oil by themselves to save costs. small edible oil production lines are designed for family or small workshop oil making. it usually consists of four stages, which are oilseed pretreatment, pressing, extraction and refining.

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.cottonseed oil extraction machinery plant cottonseed oil price,project name: cottonseed oil extraction plant output change: 200 tpd project location: mali enquire now: https://www.oilexpeller.com/enquiry/this is a complete set.

cottonseed oil manufacturing process and machinery

mechanical cottonseed oil manufacturing process is now the best choice for small, small, medium and large cottonseed oil production plants. now it is very hot to establish cottonseed oil manufacturing plants in countries such as india, pakistan, brazil, uzbekistan. if you have any interest in cottonseed oil manufacturing.

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.small/mini solvent extraction equipment for cottonseed oil price,why buy a small solvent extraction plant for cottonseed oil production? high return on investment: it requires less investment cost, and the return on investment is high and fast. easy to operate: the entire tank group for cottonseed oil extraction is easy to operate. energy saving: the power consumption of this cottonseed oil production line is small. for example, 10tpd-30tpd.

huatai brand sgs, ce and iso9001 cottonseed oil extraction machine

cottonseed extraction plant production line / oil processing machine. founded in 1953, we are a large-scale modern grain and oil machinery engineering equipment manufacturer integrating research, manufacturing and installation.

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.edible oil extraction method, edible oil extraction process price,the workshop area required for a 20tpd peanut oil processing production line is about 1000-1500 square meters, depending on the specific layout and other peanut oil processing machines you may need.