purchase indonesian palm oil production line at low price

purchase indonesian palm oil production line at low price

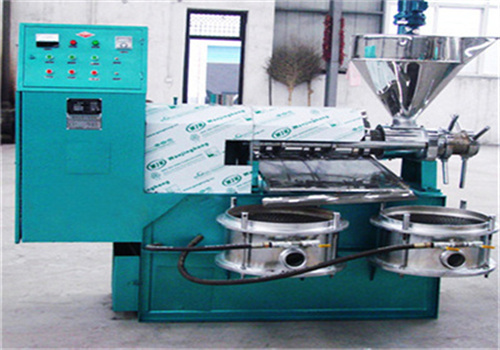

| Voltage | 380V/220V |

| Type | palm oil production line |

| Delivery time | stock or within 10 days |

| Weight | 260kgs |

| Processing Capacity | 200-600kg/h |

| Overall dimensions | 2400*900*1080mm |

| Power | 18.5 or 22kw |

| Advantage | Best price |

| Used for | Oil Making Expeller |

| After-sales Service | Technology Supporting |

| Specification | CE certification |

40tph palm oil crushing line to indonesia

palm oil prices rose sharply after 2005, but the global crisis caused a sharp drop in crude palm oil prices in 2008. although there was a strong rebound, crude palm oil prices fell to low levels again after 2011, especially due to the decline in chinese demand and the fall in oil prices (since mid-2014) that reduced the demand for palm-based biofuels.

top quality analysis: the end of the era of cheap palm oil?,march 9, 2025·kuala lumpur/jakarta: due to stagnant palm oil production and the promotion of biodiesel by indonesia, a major palm oil producer, traditionally palm oil prices may remain high in the next few years

first resources division signs agreement to acquire indonesian palm oil producer share purchase agreement for $439 million to purchase 3.1 billion shares or 91.2% of the issued and paid-in capital

factory supply

palm oil production line price in indonesia in 2025 factory price

the latest data shows that the export price of palm oil extraction machine in indonesia is $1.13/kg in 2022. based on the current trend, the export price of palm oil extraction machine in indonesia is forecast to be $1.20/kg in 2023 and $1.27/kg in 2024. indonesian palm oil exports are classified as:

The advantages of leaching method are high oil yield, high production efficiency, high degree of automation, and high quality of cake, which is conducive to subsequent utilization. But the extraction method requires the use of solvents, and the quality of the extracted crude oil is usually low, requiring processing through refining equipment before it can be consumed. In addition, solvent residue is also a concern for leaching methods.

guide to setting up palm oil processing plants in indonesia

indonesia’s coordinating minister for economic affairs airlangga hartarto said that indonesia’s total palm oil production will reach 56 million tons in 2023, and exports will reach 26.33 million tons. this figure not only shows the huge potential of indonesia’s palm oil extraction machine industry, but also brings unlimited business opportunities to investors.

The advantages of leaching method are high oil yield, high production efficiency, high degree of automation, and high quality of cake, which is conducive to subsequent utilization. But the extraction method requires the use of solvents, and the quality of the extracted crude oil is usually low, requiring processing through refining equipment before it can be consumed. In addition, solvent residue is also a concern for leaching methods.

the end of the era of cheap palm oil? output stagnates as biodiesel demand rises

high-yield palm oil press suitable for small businesses eddy martono, chairman of indonesia’s largest palm oil company, estimates that the promotion of biodiesel will cause indonesia’s exports to fall to just 20 million metric tons in 2030, a third lower than the 29.5 million tons in 2024

The advantages of leaching method are high oil yield, high production efficiency, high degree of automation, and high quality of cake, which is conducive to subsequent utilization. But the extraction method requires the use of solvents, and the quality of the extracted crude oil is usually low, requiring processing through refining equipment before it can be consumed. In addition, solvent residue is also a concern for leaching methods.

vegetable oil making machine cooking oil production line

The advantages of leaching method are high oil yield, high production efficiency, high degree of automation, and high quality of cake, which is conducive to subsequent utilization. But the extraction method requires the use of solvents, and the quality of the extracted crude oil is usually low, requiring processing through refining equipment before it can be consumed. In addition, solvent residue is also a concern for leaching methods.

cooking vegetable oil press oil mill plant

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.

vegetable oil extraction line oil making machine

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.

best sale vegetable oil extraction production line

The extraction method, also known as solvent extraction method, is based on the principle of extraction for oil production. By utilizing the similar solubility properties of oil and the solvent used, the treated oil is soaked in a solvent to dissolve the oil in the solvent, extract and dissolve it, and then separate the solvent oil from the crude oil through processes such as distillation. The extraction method for producing vegetable oil mainly involves leaching the pressed cake.

successful projects of cottonseed, sunflower seed, peanut oil press production lines

ghana 500kg/h palm oil and palm kernel oil making machine project 1tph palm oil pressing equipment project successfully installed in lagos, nigeria 5tph palm nut production line project and 1tph palm kernel oil pressing line project in uganda

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.quality parameters of cold pressed vegetable oil,comprehensive evaluation shows that the vegetable alcohol content in high vegetable alcohol vegetable oil (hcr) and low vegetable alcohol vegetable oil (lcr) after frying is in the range of 187.8–237.7 and 45.6, respectively…