kenya how to set up palm oil production line

kenya how to set up palm oil production line

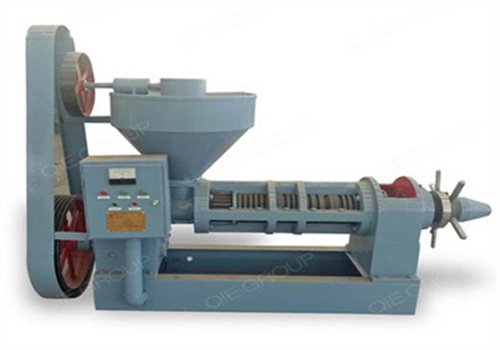

| Voltage | 380V/50HZ/3 phase |

| Type | palm oil production line |

| Condition | new |

| Weight | 1900kg |

| Processing Capacity | 120 ton/day |

| Overall dimensions | 2100*1400*1700mm |

| Power | 11kw/380v |

| Advantage | Long service life |

| Press Materials | Plant Seeds |

| After-sales Service | Video Technical Support/Online support |

| Machine Mainly | Matched with The Whole Oil Press Line |

how long does it take to build a 10tph palm oil processing plant

the time it takes to build a 10tph palm oil processing plant in kenya depends on many factors, including project planning, funding, equipment procurement, construction progress, and local regulations and approval processes. huatai petroleum machinery provides you with an approximate time frame and key steps:

top quality step-by-step guide to setting up a palm oil mill,setting up a palm oil mill involves a series of well-planned steps to ensure a smooth and successful operation. these steps cover everything from site selection to operational preparation.

oil palm tree planting and palm oil production in kenya

designed for efficiency, reliability, and high yield, this palm oil press is the ultimate solution for extracting high-quality palm oil. as global and local demand for palm oil continues to rise, kenya can take advantage of its tropical climate to expand this promising agricultural enterprise. this article takes an in-depth look at the varieties of palm trees, ecological conditions, planting methods,

factory supply oil palm planting in kenya victor matala,jul 27, 2022 · planting oil palm trees. propagation of oil palm trees is by seeds, which are first nurtured in nurseries for 12-24 months before being transplanted to the main field. the recommended planting spacing is 7m x 8m. fertilization

kenya palm oil refinery cost tips

for palm oil refineries, there are mainly two ways to obtain raw palm oil, one is to build your own palm oil processing machine, and the other is to obtain raw palm oil from palm oil manufacturers.

best price what are the costs involved in setting up a palm oil mill?,aug 10, 2024 · the costs involved in setting up a palm oil mill include palm oil mill construction cost, palm oil mill machine cost, labour cost, palm oil mill machine maintenance cost, waste management cost, staff training cost and transportation cost.

how to start palm farming in western kenya agrolearner.com

jan 10, 2023 · the steps involved in setting up a palm farm in western kenya include business planning, source of capital, purchasing quality palm seedlings, acquiring farmland, preparing the farmland, planting, weeding and pest control, fertilizing, and harvesting.

best selling set up a palm oil mill palm oil production line,set up a palm oil mill. if you want to set up a mill to produce palm oil, you must first have an in-depth understanding of this oil to determine the direction of development. palm oil is widely used for the following reasons. first, palm oil exhibits good oxidation stability during frying.

what is the step-by-step process to set up a palm oil mill

the step-by-step process to set up a palm oil mill involves four steps: conducting local market research, securing capital investment, selecting equipment manufacturers, and understanding the marketing market. palm oil machinery costs between $950-1,700,000.

large scale palm kernel oil manufacturing process flow chart goyum,to establish a palm kernel oil production plant, many aspects must be considered, including production capacity and customer requirements, the quality of the final produced palm kernel oil, palm kernel oil processing technology, etc.

how to set up a palm oil mill and how long does it take

june 03, 2020 · in order to set up a palm oil mill, you need to conduct a feasibility study based on a market study of the local situation, such as how to source palm fruits, where to sell the final product, where to get the budget, where to set up the mill, what kind of permits or certificates you need to apply for from the government, how to choose a reliable

small scale 100tph palm oil refining and fractionation plant in kenya,the pressing process needs to maximize the extraction of palm oil from the pulp, but the kernel cannot be broken, because the broken palm kernel oil will contaminate the crude palm oil and affect the quality. this palm oil refining project includes 2 production lines, one is a palm oil refining line, and the other is a palm oil fractionation line. the palm oil refinery can remove phospholipids, ffa, pigments, gums, waxes, odors and other impurities in the oil, so that we can get high-quality palm oil.

how to start a palm oil production business? nt engitech

discover the essential steps to start a successful palm oil production business. from understanding market trends to setting up a processing unit, get insights and tips on starting a profitable palm oil business.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.how much does it cost to set up a small palm oil,we can provide you with the most suitable palm fruit oil extraction solution based on various factors such as your palm fruit type, oil yield, output, geographical location, etc. for the production line required for a small palm oil processing plant, we recommend a simple and highly automated palm oil processing production line, which consists of three sets of equipment: palm fruit thresher, palm oil press and filter.

guide to establishing a palm kernel oil refinery

establishing a palm kernel oil refinery is not an easy task. our blog explains how to establish a high-quality, efficient and sustainable palm kernel oil refinery.

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.how to start a small palm oil mill in kenya,how to start a small palm oil mill in kenya. product use: production of palm oil; type: palm oil mill; main machinery: palm oil mill machine

set up a small palm oil mill production line in kenya

set up a small palm oil mill in kenya. product use: production of palm oil; type: palm oil mill; main machinery: palm oil mill machine

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.how to build a complete palm kernel oil mill? oil machine,in order to ensure the maximum output and profitability of a palm kernel oil production plant, a series of palm kernel oil processing machines are required. however, the choice of each machine depends on production capacity and investment capital.

small cottonseed oil processing plant oil plant machinery

small cottonseed oil processing plant involves several processes, such as entering the shaking room, where the cotton seeds are cleaned, and the cleaned cotton passes through abrasive sand to remove the lint in the cotton seeds. the next step is to send them to the shelling machine to remove the hard seed coat.

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.the ultimate guide to palm oil production process,prepare palm fruits for palm oil extraction machine. step 1: inspection. when they arrive at the palm oil processing unit, the palm fruits are first inspected and quality assessed to ensure that only high-quality fruits can enter the palm oil production line. step 2: sterilization.