ibadan manufacturing palm oil production line cost

ibadan manufacturing palm oil production line cost

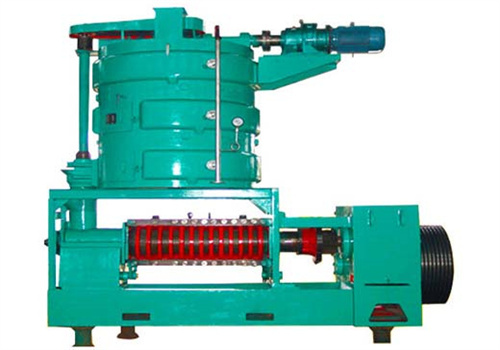

| Voltage | 380V/50HZ |

| Type | palm oil production line |

| Transport package | 3X40hq container or customized |

| Weight | 820kg |

| Processing Capacity | 130kg/h |

| Overall dimensions | 2290*750*1020mm |

| Power | 22kw/380v |

| Advantage | Low price |

| Press Series | Oil Production Line |

| After-sales Service | Free spare parts, Field installation, commissioning and training |

| Transport Package | Wooden Case Packaging |

analysis of investment costs of small and medium-sized palm oil mills

first, the ffb is transported to the receiving station, flows to the scraper conveyor, and transported to the sterilization station. in addition, the transportation cost, installation and commissioning cost, and subsequent maintenance cost of palm oil production machinery need to be considered. high-quality palm oil production machinery is usually more expensive, but in the long run it can reduce maintenance costs and improve palm oil production efficiency.

top quality oil palm by-products: how to calculate its production cost,manufacturing. production cost or manufacturing cost (riwayadi, 2006) is the cost associated with the production function. manufacturing cost includes raw materials, direct labor and manufacturing indirect costs. three products can be produced through the manufacturing process, namely, joint

what are the main costs of palm oil production and processing?

palm oil production scale: large-scale production can reduce the production cost of unit products. palm oil production technology: the use of advanced production technology can improve production efficiency and product quality, thereby reducing production costs. in short, the production cost of palm oil is determined by many factors, and it

factory supply understand the cost of a palm oil processing plant,single palm oil press price: refers to the single screw press type palm oil processing machine, the price of a small oil press is generally around us$2,000.00-us$3,000.00, while for a complex palm oil press used in industrial oil processing plants, the main motor is 18.5 kw, the packaging size is 255 x 170 x 205 cm, and the price is

how much does a palm oil mill cost?

if you want to process fresh fruit bunches (ffb) to extract crude palm oil (cpo), please contact us. we can help you maximize your profits with efficient, high-yield, and low-maintenance equipment. palm oil production line machinery and equipment. the type and quality of machinery and equipment used in palm oil mills have a direct impact on costs. basic equipment includes palm fruit sterilizer, thresher, cooker, press, clarifier and oil dryer etc. 3. infrastructure and facilities

best price palm kernel oil extraction machine price in nigeria (2025),high quality palm kernel oil processing machine palm kernel oil production line palm kernel oil extraction machine: n1.5 million; n2.3 million; price last updated on march 14, 2023. the prices in the above list are for new palm kernel oil extraction machines.

palm oil processing machine price in nigeria

multifunctional palm oil press/palm fruit processing machine/palm oil refiner; n1.1 million and n3 million; fully automatic small palm oil processing machinery small oil mill; n2.7 million and n3.5 million; palm oil pressing plant production line, 5.0 tph small palm oil mill, complete set of palm oil processing production line, small cpo plant; n5 million and n7 million

best selling how much does a palm oil production line cost?,how much does a palm oil production line cost” is the most concerned issue for customers. in fact, the price of a palm oil production line is affected by many factors, such as: the size of the processing capacity, the level of equipment configuration, the equipment supplier and other factors.

draft proposal for a palm oil mill private in oyo state

local demand for palm oil is high. it is estimated that about one in five people in nigeria consumes two litres or more of palm oil every month for cooking. there may be 5 to 10 million people living in or near ibadan, so 50 million liters or more of oil may be needed to supply this market

large scale how much does it cost to set up a palm oil mill in nigeria?,different machines are used for palm oil processing. 4. labor cost. depending on the degree of automation of the palm oil mill, the labor cost of setting up the mill will also vary. if you choose a highly automated palm oil mill production line, your labor cost will be lower. if you choose to buy a palm oil press and use manual methods

palm oil processing plant oil press setup and cost

october 204: patwill set up a palm processing plant in tripura, aiming to increase the local economy by increasing palm oil production. the launch of india’s first integrated oil palm processing unit in march 2024 marks a major step for the country in increasing domestic palm oil production. the facility will help

small scale how much does it cost to set up a palm oil mill?,aug 10, 2024 · palm oil mills have grown rapidly over the past few decades, thanks to their wide range of uses in food, cosmetics, and biofuel production. however, setting up a palm oil mill requires cost investments in multiple aspects. below, i will take you through the costs involved in setting up a palm oil mill. 1. palm oil mill construction cost

cost of setting up a palm oil mill palm oil production line

to build a palm oil mill, land is essential. a small palm oil mill production line does not require a large land area because it uses fewer machines and occupies a small area. if the processing capacity exceeds 1tph, it is necessary to equip the entire palm oil mill production line, which requires a larger land area. raw material cost

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.how much does it cost to set up a palm oil mill in nigeria,about the quality of the final product oil. if you just want to get crude palm oil, then you only need a palm oil pressing line. if you want to get refined palm oil, you need to add a refining line. if you want to get rbd palm olein, in addition to the palm oil pressing line and palm oil refining line, you also need a palm oil fractionation line. this results in different

palm oil processing machine price in nigeria technology in nigeria

our goal is to provide each customer with a tailor-made palm oil production plant and guide you to master the palm oil extraction and refining technology. fully automatic small palm oil processing machinery small oil mill; n2.7 million; n3.5 million; palm oil pressing plant production line, 5.0 tph small palm oil mill, complete set of palm oil processing production line, small cpo plant raw palm oil refinery; 1-20t/h fresh oil palm fruit plant palm fruit oil grinding pressing extraction machine, our engineers will design the right palm oil processing solution for you.

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.2025 crude palm oil production cost analysis report,procurement resources provides an in-depth cost analysis of crude palm oil production, including manufacturing processes, capital investment, operating costs, and financial expenses. +1 307 363 1045

what are the major expenses of palm oil production? finmodelslab

palm fruit/bunch (ffb) → sterilization → threshing → digestion → clarification → purification → drying → cpo → refining → bleaching → deodorization → rbd palm oil → crystallization → fractionation → rbd oleic acid and rbd stearic acidthe production of palm oil is highly dependent on the availability of fresh palm fruit bunches, which need to be transported from the plantation to the processing plant in a timely manner. the transportation of palm fruit can account for 10-15% of the total operating cost of a palm oil business. factors that influence the total cost of transportation and setting up a palm oil processing plant in nigeria

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.,more advanced and higher capacity palm oil processing machines will cost more than $500,000. a complete palm oil processing plant with a capacity of 50 tons will cost about $600,0000. and a complete palm oil production line with a capacity of 10 tons will cost about $800,000.

industrial palm oil extraction machine in the congo basin: are countries ready?

the threshed palm fruits will be transported to the cooking pot, where they are reheated with direct or indirect steam. the digester is equipped with a central shaft with stirring blades, which stir the palm fruit, fluffing the pulp and stripping it from the pit at high temperature. the mixture is then sent to the pressing equipment. the potential for expanding oil palm production in the congo basin is undoubtedly huge, according to the uk rainforest foundation. it is estimated that up to 115 million hectares of forest in the congo basin have the soil and climate required to grow oil palm. ”

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.what is the cost of building a palm oil refinery,stage 3: production cost. 1. the cost of purchasing raw palm oil. if the customer has his own palm oil crushing plant, he can directly refine the raw palm oil. if the customer does not have a palm oil crushing plant, he needs to buy it from the market, which will incur the cost of raw palm oil; 2. transportation cost;