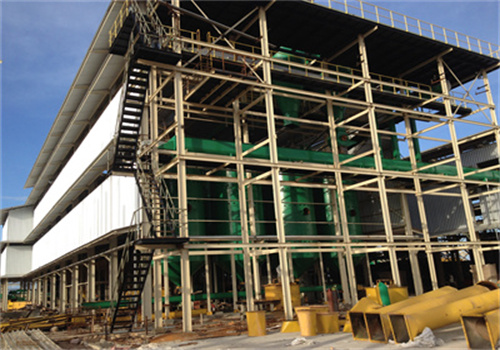

cameroon 150tpd peanut cold pressing oil production line

cameroon 150tpd peanut cold pressing oil production line

| Voltage | 380V/50HZ/3 phase |

| Type | peanut oil production line |

| Transport package | fumigated wooden packing |

| Weight | 1820kg |

| Processing Capacity | 200 t/d |

| Overall dimensions | 2300*820*1420mm |

| Power | 52kw |

| Advantage | High oil yield |

| Operation | Easy |

| After-sales Service | Service Machinery Overseas |

| Related Machine | Sheller/Oil Presser/Oil Refiner/Filling Machine |

small peanut oil production machine in cameroon

if you are planning to set up a small peanut oil production plant in cameroon, our machinery can provide a complete peanut oil production machine to expand your peanut oil production business in cameroon.

top quality cameroon large capacity twin screw peanut oil production line,affordable peanut oil production line peanut oil processing machine oil press, hydraulic oil press, oil refiner. this spiral peanut oil extraction machine is an efficient and energy-saving oil processing equipment, which is widely used in the pressing of various oil crops, such as cottonseed, soybean, rapeseed, sunflower seeds, etc.

customized peanut oil plant production line in cameroon

small peanut oil production machine in cameroon. purpose: peanut oil; type: peanut oil production line; production capacity: 50-700.500 kg/h; voltage: 220v/380v/415v; power (w): 1-30kw; dimensions (l*w*h): 1200*400*900mm3; features: multifunctional and high efficiency; warranty: 1 year; advantages: energy saving and environmental protection; material

factory supply

cold press oil machine for small enterprise peanut production line

cold press oil machine for small enterprise peanut production line in cameroon. type: peanut oil production machine; purpose: multifunctional; automation level: fully automatic; production capacity: 100%; voltage: 220v/380v; dimensions (l*w*h): 1700*1100*1600mm; weight: 880 kg; warranty: 1 year 12 months; main selling point: multifunctional; marketing

The advantages of leaching method are high oil yield, high production efficiency, high degree of automation, and high quality of cake, which is conducive to subsequent utilization. But the extraction method requires the use of solvents, and the quality of the extracted crude oil is usually low, requiring processing through refining equipment before it can be consumed. In addition, solvent residue is also a concern for leaching methods.

spiral cold peanut oil pressing plant in cameroon

spiral cold peanut oil pressing plant in cameroon. product use: production of peanut oil; type: peanut oil pressing plant; main machinery: peanut oil pressing plant machine; automation level: fully automatic; production capacity: 98%; model: dt; voltage: 220v/380v/440v; power (w): 10-50kw; size (l*w*h): according to capacity; weight

The advantages of leaching method are high oil yield, high production efficiency, high degree of automation, and high quality of cake, which is conducive to subsequent utilization. But the extraction method requires the use of solvents, and the quality of the extracted crude oil is usually low, requiring processing through refining equipment before it can be consumed. In addition, solvent residue is also a concern for leaching methods.

peanut oil production line peanut oil pressing huatai oil

peanut oil production line. peanut pretreatment process includes cleaning and shell kernel separation. according to the pressing temperature, there are two types of peanut oil pressing technology: hot pressing and cold pressing. crude peanut oil refining includes degumming, deacidification and deodorization. how to produce peanut oil?

The advantages of leaching method are high oil yield, high production efficiency, high degree of automation, and high quality of cake, which is conducive to subsequent utilization. But the extraction method requires the use of solvents, and the quality of the extracted crude oil is usually low, requiring processing through refining equipment before it can be consumed. In addition, solvent residue is also a concern for leaching methods.

vegetable oil making machine cooking oil production line

The advantages of leaching method are high oil yield, high production efficiency, high degree of automation, and high quality of cake, which is conducive to subsequent utilization. But the extraction method requires the use of solvents, and the quality of the extracted crude oil is usually low, requiring processing through refining equipment before it can be consumed. In addition, solvent residue is also a concern for leaching methods.

cooking vegetable oil press oil mill plant

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.

vegetable oil extraction line oil making machine

we can do the complete oil production plant processing from pre-pressing workshop to solvent extraction workshop to oil refinery workshop to final oil bottling workshop.this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.

best sale vegetable oil extraction production line

The extraction method, also known as solvent extraction method, is based on the principle of extraction for oil production. By utilizing the similar solubility properties of oil and the solvent used, the treated oil is soaked in a solvent to dissolve the oil in the solvent, extract and dissolve it, and then separate the solvent oil from the crude oil through processes such as distillation. The extraction method for producing vegetable oil mainly involves leaching the pressed cake.

rapeseed oil extractor price history chart [real-time

the bullish outlook for rapeseed oil extractor prices in the global market is supported by tight supply due to lower production, dwindling old crop stocks, and shortage of vegetable oils. in europe, the commodity has seen a 13% increase in price, with high values in both spot and futures markets, as weather disturbances in key producing regions such as germany, france, poland, and ukraine negatively impacted their crops.

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.palm oil press palm oil production line,palm oil is the largest vegetable oil in the world in terms of production, consumption and international trade, accounting for 30% of the world’s total oil consumption, which means that the market demand for palm oil is very large. 3. palm oil has great profits