cairo top peanut oil production line details

cairo top peanut oil production line details

| Voltage | 220v 50hz |

| Type | peanut oil production line |

| Transport package | as customers' request |

| Weight | 370kg |

| Processing Capacity | 120-150t/d |

| Overall dimensions | 2750*1100*1830mm |

| Power | 18.5-22kw |

| Advantage | High output |

| Usage | Edible Oil |

| After-sales Service | Service Machinery Overseas |

| Specification | ISO9001 |

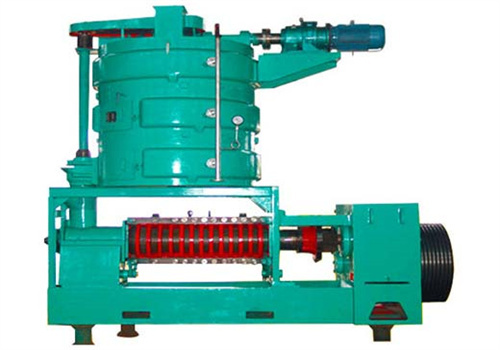

large capacity peanut oil production line

peanut oil production line in cairo, egypt is a globally oriented peanut grower, processor and exporter with established peanut cultivation and production networks in egypt and throughout africa, with sales networks throughout europe, the middle east and north africa, and the gulf region.

top quality fully automatic peanut oil production line,designed for the food processing industry, our fully automatic peanut oil production line combines advanced oil pressing technology with an automated control system. the quality and safety of each batch of peanut oil produced are guaranteed.

building a 50 tpd peanut oil plant in egypt

building a 50 tpd (tpd) peanut oil plant in egypt involves a comprehensive approach that takes into account scale, technology, compliance, and operational efficiency. the following is an outline to help guide the development of such a plant:1. business strategy and feasibility

factory supply peanut oil production line industrial development,1) fully continuous, mechanized operation, and equipped with an electrical interlocking control system. 2) the equipment is arranged in a tower structure, and the material flow relies on gravity to reduce power consumption. 3) consider the environmental requirements of modern industry.

peanut oil production line in egypt machine and iso

large capacity peanut oil production line manufacturing fy extraction. production capacity: 1 ton/hour; voltage: 380 v/50 hz; dimensions (l x w x h): 2500*1200*2200; weight: 2500 kg; main components: motor, pressure vessel, pump, plc, gear, bearing, motor, gearbox; oil application: screw oil press; function: sunflower seed press, palm press, etc.

best price edible oil pressing machinery for peanut oil production line,peanut oil press has many characteristics and advantages, making it the first choice for oil processing. in order to ensure the nutrition, flavor and safety of aromatic peanut oil and reduce costs, we use physical pressing methods in the peanut oil production line.

peanut oil production line, peanut oil pressing plant oil processing plant

hot pressing is the traditional method of peanut oil pressing. hot pressing has a high oil yield, good taste and is easy to store. it is a common oil pressing method used in households. our peanut oil production line is a comprehensive multi-stage unit designed to extract and refine oil from peanuts. from cleaning and shelling to oil pressing and refining, each stage is crucial to ensure high-quality pure peanut oil that meets commercial standards.

best selling fully automatic peanut/peanut oil production line,the peanut oil extraction equipment production line adopts pretreatment, extraction and refining processes, and uses environmentally friendly and efficient continuous automation technology to extract and refine high-quality peanut oil.

egypt raw peanut oil refining production line

egypt raw peanut oil refining production linemachine type: peanut oil refining line;production capacity: 200-6400kg/hour;dimensions (length*width*height): 2050*600*850mm;voltage: 380v/50hz/3 phases or customized;warranty: 12 months;after-sales service provided: on-site installation, commissioning, training;raw materials: peanuts;market: egypt

large scale egypt oilseeds and products 2025 usda annual revenue report,use: peanut, edible, soybean, castor, oil; type: edible oil press; production capacity: 1.8-20 tons/day; voltage: 220v, 220v /380v; dimensions (length*width*height): 800*360*550mm; customizable: yes; power (w): according to the daily capacity of the edible extruder; model: dt-; weight: 700kg edible seed oil press

high-efficiency automated peanut oil production line

our production line covers all stages from raw material processing to oil bottling, including key steps such as cleaning, crushing, peeling, roasting, pressing, filtering and refining.

small scale anderson complete guide to peanut oil production,in this peanut oil guide, we’ll examine the history of peanut production, explain how peanuts are processed into oil, and discover the various product applications for peanut oil while exploring the global growth potential of this market.

peanut oil production line, automated production line cost

one of the main uses of peanuts is oil pressing, which is the main way of peanut consumption at present. the peanut oil production line uses pressing to produce fragrant peanut oil. avoid the use of chemical solvents, baking and steaming to ensure the fragrance of the oil, and cooling water coil technology to ensure long-term storage.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.cairo peanut oil product machine cost and price,the production capabilities of peanut oil machines are as diverse as the businesses they serve. sizes and capacities range from 10-12 kg/hour to machines capable of outputting 100-200 kg/day power. for larger scale operations, machines with 20-60 ton/day operating types are available.

peanut oil pressing production line oil press extraction machine

the fully automatic peanut oil production line processes the raw peanuts into peanut oil through the automated oil making machine. the peanut oil squeezed out by the automatic peanut oil processing machine is clean, free of impurities and of excellent quality.

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.peanut oil production lines,our edible oil presses can be used on a variety of raw materials such as peanuts, beans, canola and cottonseed, sesame, olives, sunflower, coconut, cocoa, and grass seeds.

increase peanut oil yields with optimal processing

learn how to get the highest yields in peanut oil processing. gain insight into technology, machinery, and best practices to improve your oil production results.

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.key steps in peanut oil production: from raw materials to export,the peanut oil production process involves multiple steps from raw materials to oil, including cleaning, de-stone, crushing, softening, flaking, cooking, pressing, filtering, and refining. these processes are used for the following purposes:

egypt plans to increase oil exports to $21 billion by the end of the year

june 11, 2023 · egypt is working to increase its oil exports by 2023, targeting a value of $21 billion, an increase of $2.8 billion from 2022, bloomberg reported, citing government documents.

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.top 49 manufacturing companies in cairo · march 2025f6s,march 01, 2025 · detailed information and reviews about the top 49 manufacturing companies and startups in cairo 2025. get the latest updates on their products, jobs, funding, investors, founders, and more.