ghana peanut oil extraction and oil production line process flow

ghana peanut oil extraction and oil production line process flow

| Voltage | 220V |

| Type | peanut oil production line |

| Transport package | 3X40hq container or customized |

| Weight | 1300kg |

| Processing Capacity | 5-30t/d |

| Overall dimensions | 8000*2500*1370mm |

| Power | 7.5 or 11kw |

| Advantage | High quality |

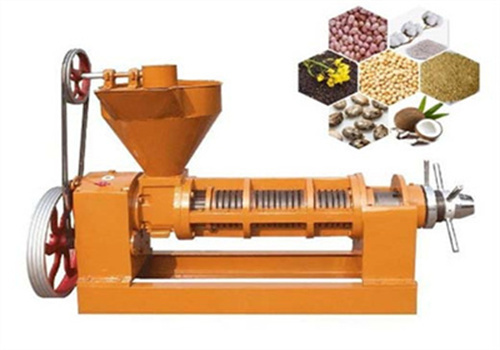

| Press Materials | Plant Seeds |

| After-sales Service | Online Service |

| Related Machine | Sheller/Oil Presser/Oil Refiner/Filling Machine |

peanut oil manufacturing process flowchart

the peanut oil manufacturing process is divided into two methods, the first is mechanical pressing and the second is solvent extraction. mechanical pressing can extract 85% of the oil, and the rest of the oil is extracted by solvent extraction.

top quality peanut oil processing ppt edible oil extraction machine,peanut oil solvent extraction equipment is a process that uses solvents to extract oil from pressed peanut cakes. peanut oil solvent extraction process flow chart:

making peanuts peanut oil in northern ghana west africa

in this video, we explore the production process of organic peanut oil in northern ghana… organic peanut oil or peanut oil has many health benefits.

factory supply peanut oil processing niftem,peanut oil extraction method & bull; also known as leaching method, uses organic solvents to dissolve oil, sprays and soaks oil-containing materials, and finally separates oil from materials.

peanut oil extraction equipment production line process

our refined peanut oil production line is a set of professionally designed automated production equipment, mainly used for efficient extraction of high-quality peanut oil. the peanut oil extraction equipment production line adopts pretreatment, extraction, and refining processes, and uses environmentally friendly and efficient continuous automation technology to extract and refine high-quality peanut oil.

best price peanut oil production line, automated production line cost,one of the main uses of peanuts is oil pressing, which is currently the main way to consume peanuts. peanut oil production line is a process of extracting aromatic oil from peanut kernels using a unique pressing technology. peanut is a high-oil oil crop. at present, the unique pressing process is suitable for extracting high-flavor edible oil, truly realizing “chemical-free production”.

what steps are involved in peanut oil processing?

the fully automatic peanut oil production line integrates the latest intelligent technology to improve production efficiency. ensure product quality and meet market demand. the production of peanut oil in an oil mill involves multiple steps from raw materials to oil, including cleaning, de-stone, crushing, softening, rolling, cooking, pressing, filtering and refining.

best selling peanut oil production process: from farm to bottle,aug 14, 2024 · the production of peanut oil can be divided into two main stages: mechanical pressing and solvent extraction. initially, mechanical pressing can remove about 85% of the oil from peanuts. solvent extraction is then used to extract the remaining oil.

what are the processing steps for making peanut oil? _blog

depending on the customer’s investment budget and production scale, the processing steps for making peanut oil are slightly different. next, we will take the standard peanut oil production line as an example to introduce the processing steps.

large scale peanut oil manufacturing processom- linkedin,mar 03, 2023 · in mechanical pressing technology, the peanut oil production process is divided into three stages: peanut preparation, pressing, and crude oil refining. to extract peanut oil, peanuts must first be pre-processed by professional seed cleaning equipment. the cleaned peanut seeds will be sent to the oil press plant and then pressed into oil by the oil press. however, crude peanut oil usually contains many impurities, so for edible oil, the pressed peanut oil needs to be extracted in the leaching plant first, and then the extracted oil is sent to the refinery for further processing.

ghana peanut oil pressing and refining production line

the characteristics of the peanut oil production line and pressing line are: (1) the extraction adopts a pure physical pressing method, and the entire production process completely avoids the contact between the raw materials and chemical solvents; (2) the elimination of solvents and other unfavorable refining processes that affect the quality of the finished oil

small scale peanut oil processing technology peanut oil press extraction machine,the peanut oil solvent extraction plant is a part of the peanut oil processing machine, which is designed to extract oil directly from the pressed peanut cake. this chapter introduces the peanut oil processing technology. first, the pretreatment technology of high-temperature cold-pressed peanut oil and the peanut pressing technology are introduced. then the peanut oil extraction technology, including leaching and separation technology, is discussed.

ghana 200 tons per day peanut processing line

locally grown peanuts are incorporated into the production of nutritious rutf therapeutic food for the peanut butter project. develop a process to safely sort peanuts from debris and eliminate aflatoxin-contaminated peanuts. design a cost-effective roasting process while providing employment opportunities for local residents. machinery selection.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.ghana peanut oil production line edible oil processing machine,ghana peanut oil production line/peanut oil production process. type: peanut oil production line; purpose: peanut oil; automatic level: automatic; production capacity: 100%; voltage: local voltage; dimensions (length * width * height): as required; weight: as required; warranty: 1 year

peanut oil production line steps

the fully automatic oil press adopts a hydraulic box structure, which truly realizes a series of automated operations such as automatic feeding, automatic pressing, and automatic cake discharge. the peanut oil production line includes several processes such as cleaning and drying process, shelling process, cooking process, pressing process, etc.

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.ghana high-quality peanut oil refining machine,feb 21, 2020 · types of ghana cooking peanut oil refining machine. peanut oil manufacturing process with flowchart goyum production capacity: 45-400kg/h dimensions (l*w*h): 1440x870x1180mm, other product advantages: high. how to refine peanut oil processed in small workshops?

ghana large peanut oil refining and processing machine

large oil mills usually use pre-pressing and leaching process to produce peanut oil. the pre-pressing and leaching process is to squeeze out most of the oil first, and then solvent leaching the peanut cake to further extract the residual oil in the oil cake and increase the oil yield.

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.peanut oil press peanut oil processing plant design/peanut oil,oil press peanut oil processing plant design/ghana peanut oil extraction process. type: peanut oil extraction machine; purpose: pressing oil; automation level: semi-automatic; production capacity: 50-5000; voltage: 220 / 380v; dimensions (length * width * height): 1500 * 600 * 1200; weight: 800kg; warranty: 1 year; main selling point: energy saving; marketing machinery

botswana cost-effective peanut oil refining machine

botswana high capacity peanut oil pressing equipment. function: refined edible oil processing; after-sales service: on-site installation, commissioning and training; dimensions (l*w*h): 1020*910*850mm; production capacity: 1-10 tons per day; voltage: 220v; weight: 160kg; power: 3kw; certification: ce/national credit certificate

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.extraction of coconut oil by small scale processors in ghana,this paper explores the various procedures and constraints of processing coconut oil by small scale processors in the jomoro district of the western region of ghana. thirty (30) respondents from four randomly selected villages with large production and processing of coconut oil were interviewed through a questionnaire survey.