the best palm kernel cold pressed oil production line in sabah

the best palm kernel cold pressed oil production line in sabah

| Product Name | palm kernel oil production line |

| Power | 18.5kw |

| Press series | fourth |

| Voltage | 220V/380V |

| Weight | 2300kg |

| Processing Capacity | 10-30 t/d |

| Overall dimensions | 2250*1650*1660mm |

| Transport Package | Wooden Case |

| Advantage | Best price |

| Transport Package | Export Fumigation-Free Wooden Box |

| After-sales Service | Free spare parts, Video technical support |

new palm oil processing plant sells well

in july 2016, kenso opened a new oil palm processing plant. the plant is located on 30 acres of land in kenso’s sapang oil palm estate in the kunak district of sabah, eastern malaysia. with a capacity to process 250,000 tons of fresh fruit bunches per year, the plant will serve kenso’s sabah plantation and other neighboring areas

kunak refinery sdn. bhd. swit kinabalu,kunak refinery sdn bhd (kpsb) is the first palm oil refining and palm kernel crushing plant owned by the sabah state government, located in kunak. the plant was put into operation on may 14, 2007, with a production capacity of 1,500 metric tons of palm oil (cpo) and 400 metric tons of palm kernel (pk) per day.

palm kernel oil manufacturing flowchart

palm fruit or palm kernel has been processed for edible oil in africa for thousands of years, producing a brightly colored, fragrant oil that is an essential ingredient in traditional african cuisine. palm kernel oil processing. the mechanical extraction process is suitable for small, medium and large capacity operations.

production and processing of palm and palm kernel oil.the oil palm industry has proven to be one of the most important industries in malaysia and indonesia. as of 2009, there are 4.69 million hectares of oil palm plantations in malaysia, including 2.4 million hectares in peninsular malaysia, 1.36 million hectares in sabah, and 710,000 hectares in sarawak (mpob, 2009).

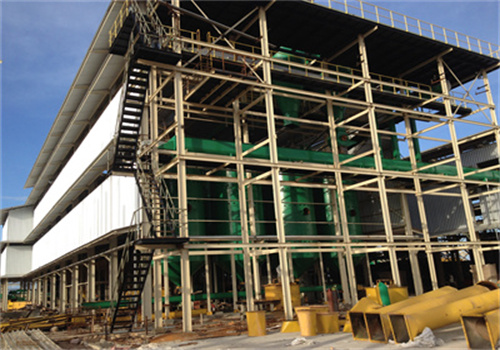

large capacity palm kernel oil production line

a palm kernel processing plant tailored for you. according to different production capacities and different requirements of customers for products, our company can reasonably select and combine the palm kernel oil production process, select the best process flow, as well as advanced equipment manufacturing and automatic control systems to provide customers with perfect

5tph palm oil production line oil press,batch type is ideal for small palm oil production (1-20tpd), while semi-continuous refinery is the best choice for medium and large production lines (20-50tpd), and fully continuous refining line (50-600tpd) is most commonly used in large palm oil production plants.

household palm oil production line

after palm oil is pressed, the solid part discharged from the screw press is a mixture of fiber and nuts. at the palm kernel recovery plant, the nuts and fibers are separated by physical methods. the nuts are sent to the palm kernel pressing and solvent extraction plant to be made into palm kernel oil, while the fibers are used as biomass fuel for the boiler on site.

self-made cold pressed palm kernel oil is simple and easy,self-made cold pressed palm kernel oil is simple and easy. hi family thanks for visiting, guys, you may want to check out these oil videos; how to make avocado oil press…

large automated palm kernel oil pressing production line

the automated palm oil pressing line is a highly efficient equipment professionally produced and sold by qie group, mainly used for the extraction and production of palm oil. the set of equipment includes a spiral palm oil extractor, which can effectively handle production capacity from 1tph to 40tph, with a maximum processing capacity of

palm kernel oil production line – qie grain and oil machinery,qie grain and oil machinery co., ltd. is a leading chinese manufacturer of oil processing, palm oil milling, oil extraction, oil press and vegetable oil production line equipment. the extraction of palm kernel oil mainly includes two methods, mechanical extraction and solvent extraction. i mechanical extraction mechanical extraction

physical, chemical and microbiological properties of mixtures

physical, chemical and microbiological properties of hydrogenated palm kernel oil (pko) and cold pressed rice bran oil (rbo) as raw materials for the production of liquid and powdered non-dairy products

homemade palm kernel oil from scratch using cold pressing,homemade palm kernel oil from scratch using cold pressing method @veeba’s kitchen.

physical, chemical and microbiological properties of blends

physical, chemical and microbiological properties of hydrogenated palm kernel oil (pko) and cold pressed rice bran oil (rbo) as raw materials for the production of liquid and powdered non-dairy products

a practical review of the phases of palm kernel oil production,palm kernel is the product of the oil palm tree (elaeis guineensis). this article provides information about the composition of palm kernel and palm oil, the uses of palm kernel oil (pko), and the extraction method of palm

what is cold pressed oil and its uses and benefits

storage: store cold pressed oil in a dark, airtight container to preserve its freshness and prevent oxidation. health benefits of cold pressed oil. cold pressed oil is a smart investment in your health and one of nature’s most nutrient-rich food sources.

high quality palm kernel oil press for cold pressed palm kernel oil,palm kernel oil press can be used alone or in conjunction with other palm kernel oil processing equipment: palm kernel crusher and separator, palm kernel cleaning equipment, palm kernel cooking equipment, palm kernel oil filtering equipment, palm kernel oil refining equipment

dr lovely palm kernel oil pure cold pressed organic

: cold pressed palm kernel carrier oil is non-gmo and considered non-allergenic. palm kernel oil and palm oil are often confused. the two can be used interchangeably, but there are differences. palm oil comes from the palm fruit, while palm kernel oil comes from the kernel.

best price palm kernel oil extraction methods provided by palm kernel oil press,for the first time since 2004, the total volume of palm oil and palm kernel oil exceeded that of soybean oil, the world’s main edible oil. there are major differences between palm oil and palm kernel oil, and here we will only discuss the extraction of palm kernel oil. mechanical extraction

conversion of industrial organic waste from cold pressing

the process flow diagram shows the extraction of avocado oil from a cold pressed avocado oil production line in kerikeri, new zealand, using a three-phase decanter system during the early harvest season. the yields of avocado wastewater, skin, seeds, pomace and oil are reported as averages of samples collected on three different production days during the week.

large palm and palm kernel oil production and processing in nigeria,the nigerian vegetable oil market features packaged palm kernel oil for home and commercial food frying. more than 60% of the refineries in nigeria are built using palm kernel oil as feedstock. this is because the processing of palm kernel oil involves degumming, bleaching, deodorizing, cooling, and packaging.

[beginner’s guide] how to process palm kernel oil

how to make cold pressed palm kernel oil at home. cold pressed palm kernel oil can be made at home using simple tools and methods. here are the steps to follow:step 1. get high quality palm kernels. look for fresh, high quality palm kernels from a reliable source. you can buy them from local markets or online stores.step 2. clean

small buy high quality palm kernel oil processing machine in malaysia,palm kernel oil processing machine. palm kernel oil processing machine is one of the most important equipment in palm kernel oil processing. our large palm kernel oil processing machine has a large capacity and is mainly used in medium and large oil production plants. it can be divided into two types: one is hot processing, including steam

palm kernel oil press for cold pressed palm kernel oil

this palm kernel oil extraction machine is specially designed for pressing palm kernel oil according to the hard characteristics of palm kernel. it uses the world’s most recognized palm oil processing technology to obtain palm kernel oil. this type of palm kernel oil press has the characteristics of reasonable structure and convenient operation.

medium scale (pdf) palm oil economic performance and r&d in malaysia,despite the decline in crude palm oil (cpo) production due to labor shortages and limited palm oil supply during the covid-19 pandemic, the palm oil production line industry performed better in 2021 than in 2020.

palm kernel oil plant palm oil production line

the palm oil content is very high: ordinary fresh fruit: 46~50%, palm kernel: 50~55%. as a professional manufacturer of palm kernel oil mill, we can provide a full set of palm oil mill, a full set of palm kernel oil grinding plant and a full set of palm kernel oil refining machiney and cpko fractionation plant.

factory price palm oil and palm kernel oil production and processing,the main products obtained from the extraction process of oil palm fruits are crude palm oil (cpo) and palm kernel oil (pko) [4]. the production of palm oil often results in some residues

100% pure palm kernel oil, cold pressed (3.40 fl oz, zinc

buy 100% pure palm kernel oil, cold pressed (3.40 fl oz, zinc:) 3-pack on amazon.com and get free shipping on eligible orders

automatic avocado oil extraction process: cold pressing method,in a complete review of avocado oil (jacobsberg, 1988), the author argues that mechanical extraction methods are better than cold pressing extraction: complete process plant from oil production linen on commercial useonly in the late 1990s did a processing company in new zealand start producing cold pressed avocado oil (cpao) as

how to extract cold pressed oil from sunflower seeds? _blog

if you want to engage in related business, build a cold pressed sunflower oil production line, or want to know more about sunflower oil processing plants. you can contact us at any time, we have a professional sales team and engineer team, can provide you with advice to meet your needs.

hot and cold pressed edible oil production line details and prices,corn oil production line, view peanut rapeseed oil rapeseed oil. corn oil production line, us dollars/set, brand new, peanut oil, hot and cold press. source: dingzhou yongsheng grain and oil. sunflower oil production line. after squeezing, the oil yield is higher when cooked, and the hot pressed oil is more fragrant.