angola peanut oil processing production line process flow

angola peanut oil processing production line process flow

| Voltage | 380V |

| Type | peanut oil production line |

| Delivery date | two weeks |

| Weight | 1500kg |

| Processing Capacity | 10-120t/d |

| Overall dimensions | 2900*1850*3240mm |

| Power | 15 or 18.5kw |

| Advantage | Multifunctional |

| Mechanical Test Report | Provided |

| After-sales Service | Video technical support, Online support |

| Warranty | One Year |

peanut oil manufacturing process flowchart

the peanut oil manufacturing process is divided into two methods, the first is mechanical pressing and the second is solvent extraction. mechanical pressing can extract 85% of the oil, and the rest of the oil is extracted by solvent extraction.

top quality fully automatic peanut/peanut oil production line,the peanut oil extraction equipment production line adopts pretreatment, extraction, and refining processes, and uses environmentally friendly and efficient continuous automation technology to extract and refine high-quality peanut oil.

peanut oil production line, automatic production line cost

one of the main uses of peanuts is oil pressing, which is the main way to consume peanuts at present. peanut oil production process and operation points. in order to ensure the nutrition, flavor and safety of fragrant peanut oil and reduce costs, we use physical pressing in the peanut oil production line.

factory supply oil processing steps of peanut oil production line,the fully automatic oil press adopts a hydraulic box structure, which truly realizes a series of automated operations such as automatic feeding, automatic pressing, and automatic cake discharge. the peanut oil production line includes multiple steps: cleaning and drying process, shelling process, cooking process, and pressing process.

9.10.2.2 peanut processing united states environmental protection agency

the main process steps include processing peanuts for eating in shell and shelling peanuts for other uses. some peanuts are processed for baking in shell. figure 9.10.2.2-1 is a typical flow chart for processing peanuts in shell.

best price peanut oil production line mechanical steps,may 21, 2019 · peanut oil production line-qie valley. introduction to pre-pressing process: 1. flow chart: peanut seeds → metering → cleaning → crushing → cooking → tableting → pre-pressing → pressing cake to packaging line. ↓. crude oil filter → to refinery. 2. process characteristics: 1) fully continuous and mechanized. peanut oil processing technology

the magical journey of peanut oil production line

november 13, 2024 · peanut oil production line. to produce edible oil that meets national standards, crude oil needs to be processed by oil refining equipment to remove impurities in crude oil and improve the quality of peanut oil. the peanut oil refining process is as follows: crude peanut oil → hydration → degumming → alkali refining → deacidification

best selling peanut oil production line peanut oil press huatai oil,peanut oil production line. the peanut pretreatment process includes cleaning and shell and kernel separation. according to the pressing temperature, there are two types of peanut oil pressing processes: hot pressing and cold pressing. crude peanut oil refining includes degumming, deacidification, and deodorization. how to produce peanut oil? processing

edible oil pressing machinery for peanut oil production line

the peanut oil press has many characteristics and advantages and is the first choice for oil processing. peanut oil production process and operation points in order to ensure the nutrition, flavor, and safety of fragrant peanut oil and reduce costs, we use physical pressing in the peanut oil production line.

large scale what steps are involved in peanut oil processing?,the fully automatic peanut oil production line integrates the latest intelligent technology to improve production efficiency. ensure product quality and meet market demand. the production of peanut oil in an oil mill plant involves multiple steps from raw materials to oil, including cleaning, de-stone, crushing, softening, rolling, cooking, pressing, filtering, and refining.

peanut oil extraction equipment production line process flow

our company’s refined peanut oil production line is a set of professionally designed automated production equipment, mainly used for efficient extraction of high-quality peanut oil. the peanut oil extraction equipment production line adopts pretreatment, extraction, and refining processes, and uses environmentally friendly and efficient continuous automation technology to extract and refine high-quality peanut oil.

small scale peanut oil processing technology, peanut oil processing needs to consider different processing links and related oil processing equipment. the steps of seed preparation, oil pressing, extraction and refining must be performed skillfully to produce the highest quality oil,peanut oil solvent extraction equipment is a part of the peanut oil processing machine, which is designed to extract oil directly from the pressed peanut cake. this chapter introduces peanut oil processing technology. first, the pretreatment technology of high-temperature cold-pressed peanut oil and peanut pressing technology are introduced. then the peanut oil extraction technology, including leaching and separation technology, is discussed.

low-cost peanut oil processing plant

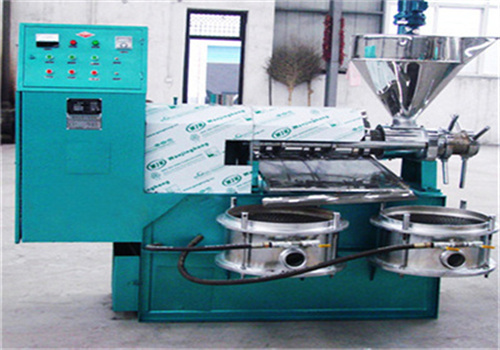

the peanut oil press consists of a feeder, a gearbox, a pressing chamber, and an oil receiver. peanuts have a high oil content, and its industrial oil-making process generally adopts a pressing process, that is, mechanical pressing is used to extract oil. the primary processing of peanuts includes cleaning and shelling.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.angola cylinder pressed edible oil production line,the process of making edible oil using our small oil production line involves several basic steps to ensure the highest quality and efficiency. raw material pretreatment: the process starts with selecting high-quality raw materials, such as seeds or nuts, which are then cleaned using equipment such as seeds to remove any impurities.

what are the processing steps for making peanut oil? _blog

depending on the customer’s investment budget and production scale, the processing steps for making peanut oil are slightly different. next, we take a standard peanut oil production line as an example to introduce the processing steps of peanut oil.

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.peanut oil production process: from farm to bottle,aug 14, 2024 · if mechanical pressing technology is used, the oil production process includes three key stages: peanut preparation, pressing and refining of crude oil. the whole extraction process involves five steps: cleaning, shelling, cooking, pressing and filtering.

peanut oil edible oil press processing and production line

peanut processing line, peanut oil production line. peanut pressing method to extract oil is conducive to maintaining the inherent flavor and aroma of peanut oil. the pressing method can be divided into ordinary peanut oil extraction process and special peanut oil extraction process. get price

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.peanut oil processing niftem,peanut oil pressing process • the peanuts obtained from the pretreatment method undergo pressing technology to extract oil from the peanuts. the oil in peanuts is mainly extracted by two pressing methods: high temperature pressing method cold pressing method

botswana 80 tons groundnut oil production plant/automation

we can provide small, medium and large industrial scale groundnut oil processing plants. botswana groundnut (peanut) market insights selina production. in 2019, the groundnut production in botswana was 1,408 tons, with an estimated average change of -75.62%.

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.angola cold combined ground nut oil processing plant,angola cold combined ground nut oil processing plant. application: peanut oil; type: peanut oil processing machine; production capacity: 360-480kg/day; power: varies with capacity; dimensions (l*w*h): 600*306*780mm; weight: 550kg, 550kg; after-sales service: online technical service; market: angola