ethiopian peanut oil production line process flow

ethiopian peanut oil production line process flow

| Voltage | 110v/220v |

| Type | peanut oil production line |

| Automatic grade | semi-automatic |

| Weight | 510kg |

| Processing Capacity | 1-1.5t/d |

| Overall dimensions | 800*900*1050mm |

| Power | 18.5-22kw |

| Advantage | best maufacturer |

| Press Materials | All Oil Seeds |

| After-sales Service | Engineers available to service machinery overseas |

| Machine Mainly | Matched with The Whole Oil Press Line |

peanut oil manufacturing process flow chart

the peanut oil manufacturing process is divided into two methods, the first is mechanical pressing, and the second is solvent extraction. mechanical pressing can extract 85% of the oil, and the rest of the oil is extracted by solvent extraction.

top quality addis ababa edible oil production overview investment,ethiopia’s demand for edible oil is growing at an annual rate of 6.8%. it is expected that by 2020, the national demand for edible oil will increase from 671,076 tons in 2019 to more than 1,395,685 tons.

peanut oil production line, automated production line cost

one of the main uses of peanuts is oil pressing, which is the main way to consume peanuts at present. peanut oil production process and operation points. in order to ensure the nutrition, flavor and safety of fragrant peanut oil and reduce costs, we use physical pressing in the peanut oil production line.

factory supply peanut oil production line/vegetable oil production line ethiopia,peanut oil pretreatment and pre-pressing sections are important components of peanut oil processing equipment. the pretreatment process for extracting peanut oil usually includes cleaning, crushing, rolling, steaming and frying. the purpose of these processes is to put the peanut seeds in the best state for oil extraction, ensure easy oil extraction, and ensure the smooth progress of the subsequent peanut oil production process. peanut oil production line seed oil press. the peanut oil production line is a process of extracting aromatic oil from peanut kernels using unique pressing technology. peanut is an oilseed with high oil content.

peanut oil production line industry development

pre-pressing process introduction: 1. flow chart: peanut seeds → metering → cleaning → crushing → cooking → tableting → pre-pressing → pressing cakes to packaging production line. crude oil filter → sent to refinery. 2. process characteristics: 1) fully continuous mechanized operation, equipped with an electrical interlocking control system.

best price ethiopian factory 1-3tpd peanut oil production line,as a professional oil press factory, our company gives priority to providing high-quality products at competitive prices. 10tpd pressing 3tpd peanut oil refining equipment. moisture content: 5-10%; temperature: 105-110 degrees; time required: 60 minutes. oil extraction process: soybeans and peanuts can be extracted after pretreatment.

fully automatic peanut/peanut oil production line

the peanut oil extraction equipment production line adopts pretreatment, extraction and refining processes, and uses environmentally friendly and efficient continuous automation technology to extract and refine high-quality peanut oil.

best selling ethiopia high-quality peanut oil processing plant,ethiopia high-quality peanut oil processing plant. purpose: refined peanut oil extraction machine price; production capacity: according to capacity; voltage: 220v, 380v, 440v; power (w): 5.5kw, 7.5kw, 15kw, 18.5kw; size (length * width * height): 430*230*350; weight: 1050 kg; certification: ce, bv, iso; name: processing peanut oil extraction machine; raw materials: fresh peanuts

peanut oil production line steps

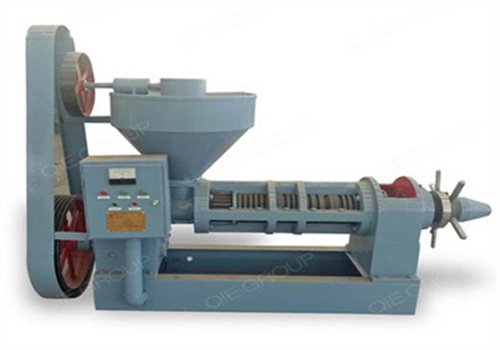

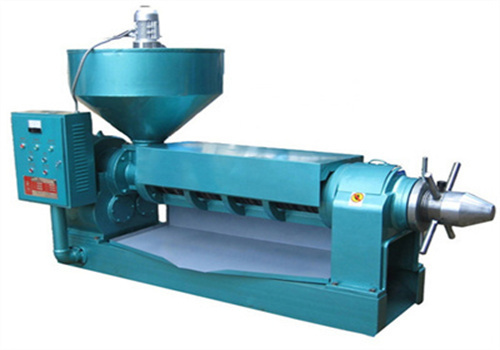

the automatic oil press adopts a hydraulic box structure, which truly realizes a series of automated operations such as automatic feeding, automatic pressing, and automatic cake discharge. the peanut oil production line includes multiple processes such as cleaning and drying processes, shelling processes, cooking processes, and pressing processes.

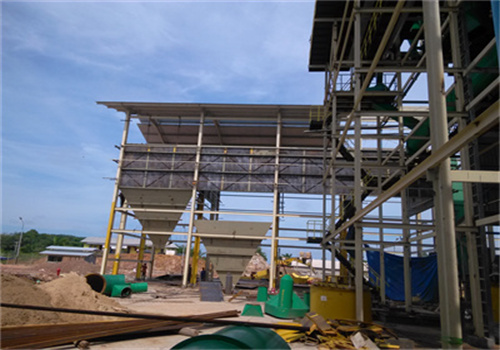

large scale use ethiopian fully automatic peanut oil mill plant manufacturers,during the cleaning process, the raw materials are cleaned by removing immature, damaged and moldy grains. 1.2 peanut oil production line process flow. 10 tpd automatic oil mill plant is a powerful business solution for efficient and automated multi-seed oil extraction.

peanut oil production line edible oil press extraction machine

the peanut oil press has many characteristics and advantages, making it the first choice for oil processing. peanut oil production process and operation points to ensure the nutrition, flavor and safety of aromatic peanut oil and reduce costs, physical pressing method is used in the peanut oil production line.

small scale peanut oil production line large project cost,we can provide equipment for processing peanuts/groundnuts of different capacities. they have unparalleled experience in producing precise drawings detailing foundation loads, building dimensions and overall plant layout design that can be tailored to individual needs.

peanut oil production line

we can provide equipment for processing peanuts/groundnuts of different capacities. they have unparalleled experience in making precise drawings, detailing the foundation load, building dimensions and overall factory layout design, and tailor-made according to individual needs.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.9.10.2.2 peanut processing united states environmental protection agency,the main process steps include processing peanuts for in-shell consumption and shelled peanuts for other uses. some peanuts are processed for in-shell roasting. figure 9.10.2.2-1 shows a typical flow chart for in-shell peanut processing.

peanut oil processing technology, peanut oil processing requires consideration of different processing links and related oil processing equipment. the steps of seed preparation, oil pressing, extraction and refining must be performed skillfully to produce the highest quality oil

peanut oil solvent extraction plant is a part of the peanut oil processing machine, which is designed to extract oil directly from the pressed peanut cake. this chapter introduces peanut oil processing technology. first, the pretreatment technology of high temperature cold pressed peanut oil and peanut pressing technology are introduced. then the peanut oil extraction technology, including leaching and separation technology, is discussed.

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.peanut oil processing ppt edible oil extraction machine,the peanut oil refining process effectively removes impurities and harmful substances from the oil. the quality and stability of the oil are improved by processing steps such as degumming, deacidification, decolorization and deodorization. peanut oil solvent extraction plant is a process that extracts oil from pressed peanut cakes through solvents. peanut oil solvent extraction process flow chart:

edible oil consumption turnkey project supply in ethiopia

oil pressing process in ethiopian oil plant. use: edible oil; production capacity: 30-4000kg/h; model: edible oil making machine; voltage: according to your requirements; power (w): according to your requirements; dimensions (l*w*h): according to your requirements; weight: according to your requirements; certification: iso9001; control: plc

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.continuous peanut oil refining production line in ethiopia,continuous peanut oil refining production line in ethiopia. production capacity: 1-500t/d; model: dt-zyj02; voltage: 220v/380v; power (w): 10-50kw; dimensions (l*w*h): 46*32*12m; weight: 30 tons; certification: iso9001; raw material: shea butter; application: crude oil refinery; product name: crude oil shea seed oil refinery; processing capacity

complete peanut oil production line by india’s largest peanut producer

discover the top 5 states leading in peanut production in india. explore how gujarat’s dominance and andhra pradesh’s innovative agriculture drives growth in peanut cultivation globally

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.coconut oil pressing manufacturing process flow chart price,uses: peanut, coconut, soybean, castor, rapeseed, sesame, cooking, copra, grape seed, shea, safflower, germ, seed, oil type: coconut oil production line production capacity: 9-11 tons/day