philippine exporter edible medium oil refining equipment

philippine exporter edible medium oil refining equipment

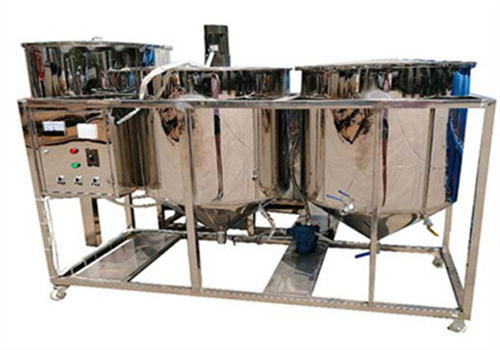

| Product Name | edible oil refining equipment |

| Weight | 550kg |

| Processing Capacity | 1-5 ton per day |

| Power | 7.5-11kw |

| Voltage | 380V |

| Overall dimensions | 1010*850*870mm |

| Material | 304 Stainless Steel |

| Advantage | High oil yield |

| Working pressure | 0.3-0.4mpa |

| After-sales Service | Field maintenance and repair service |

| Oil Press Type | Hydraulic/Screw Spiral |

wilmar edible oils philippines, inc. oil refinery

wilmar edible oils philippines, inc. (weopi) is a subsidiary of wilmar international limited, a leading asian agri-business group, engaged in oil palm cultivation, edible oil refining, oilseed

small 20tpd copra oil plant refiner in philippines,this is one of our projects in philippines. a medium-sized copra oil plant, including 20tpd oil pressing line and 10tpd oil refining line. the daily capacity is to process 20 tons of copra (dried coconut) and obtain 10 tons of refined coconut oil.

crude edible oil refining equipment and turnkey plant cost

we can provide edible oil refining plant equipment with capacities from 50 tons/day to 4,000 tons/day for soybean oil, rapeseed oil, sunflower oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fat, chicken fat, butter, fish oil, etc.

big 20tpd edible coconut oil refining machiney production plant in the philippines,jul 18, 2015 · 20tpd semi-continuous coconut oil refining machiney production plant was successfully completed in the philippines in may 2015. the plant was purchased by a former customer who planned to expand the production of edible coconut oil.

2017 coconut oil mill/refinery summarypca.gov.ph

x lanao milling corporation oil mill/refinery cno, rbdo, copra iligan city n/a johnny v. sim tel. 221-5001/ fax-221-3088 xii matutum oil mill & refinery oil mill & refinery rbd cxp silway 7, polomolok, south cotabato n/a rebelita c. gaceta xiii philippine global coconut oil mill inc. oil mill-refinery/exporter

high quality philippine 10-50t/d edible oil refining machiney,10-50t/d edible oil refining machiney equipment export. type: oil refining machiney; after-sales service: free spare parts, on-site installation; dimensions (l*w*h): 1970*700*780mm; production capacity: 220-260t/d; voltage: 220v/110v; weight: 400kg; power: 18.5-22kw; advantages: top brand; usage: any edible crude oil

philippine edible oil equipment suppliers and exporters

let us match you with the right edible oil equipment suppliers, exporters and manufacturers for your sourcing needs. simply fill out the rfq form to start getting quotes from the right suppliers. spend 1 minute posting your buying requirements! join now for free

manila small capacity edible oil refining machine,this is one of our projects in philippines, a medium-sized copra oil plant, including 20tpd oil extraction line and 10tpd oil refining line. the daily capacity is to process 20 tons of copra (dry coconut) and obtain 10 tons of refined coconut oil. it is designed for producing edible coconut oil from dry coconut (dry coconut).

philippines petroleum exporting strong and durable edible oil

oil material: stainless steel and carbon steel; application: small edible oil plant; advantages: low oil residue small oil press; raw material: palm, etc; function: making edible oil; energy drive: electric motor or diesel engine; main markets: zambia, ghana, nigeria, india, philippines; price level: factory low price screw oil press

philippines oil rugged edible oil processing,type: edible oil pressing plant; production capacity: 400kg/h; voltage: 200v-240v; dimensions (l*w*h): 1620*580*1195mm; can it be customized: yes; motor power: 18.5kw; model: kernel oil extractor; weight: 950 kg; warranty: 1 year except spare parts; application: food industry/home use; after-sales service provided: free spare parts

edible peanut oil refining machine philippines supplier

high quality refinery edible oil refining technology and equipment. chemsta vegetable oil fat refining production line is used to refine various oils, including soybean oil, rapeseed oil, cottonseed oil, peanut oil, sunflower seed oil, corn germ oil and rice bran oil.

philippines edible oil company list,matutum oil mill and refinery was established in 2013 and is dedicated to producing high-quality coconut oil by-products. the company is located in the southern philippines where the best coconuts are grown.

philippines 20tpd small edible oil refining machiney project

small refinery project equipment exported to philippines. the production capacity is 20 tons per day. this is a small semi-continuous edible oil refining machiney designed for crude coconut oil.

edible oil refining machiney in philippines,let oil refinery machine meet your sourcing needs and find the right edible oil refining machiney suppliers, exporters and manufacturers for you. simply fill in the rfq form to start getting quotes from the right suppliers.

edible oil suppliers and manufacturers in philippines

find edible oil suppliers. get the latest ex-factory prices for edible oil. request quotes and connect with manufacturers and edible oil b2b suppliers in philippines. page 1

where to buy coconut oil press in philippines?,coconut oil press is a screw type oil press suitable for oil extraction or pre-extrusion. for small and medium coconut oil mills, the screw coconut oil press is a cost-effective machine from these aspects, including oil output, investment cost, operation and maintenance.

small edible coconut oil refining machiney export to philippines

we have a new agreement with a philippine customer for a small edible oil refining machiney. this small scale refinery is designed based on semi-continuous refining process. the client wants to set up a refinery to process rbd coconut oil from copra for cooking.

2017 coconut oil refining machiney summary pca.gov.ph,xiii philippine global coconut oil mill inc. oil mill refiner/exporter crude oil/copra cake/powder, refined bleached agent, deodorized coconut oil, coconut fatty acid distillate amc building montilla blvd.,tandang sora, butuan city purok ramos, san luis, gingoog city dr. allan michael m. cagalingan/president 085-341-3244/fax: 085-341-4568, 088-861

# what equipment is needed for edible oil refining?

with the growing demand for edible oil in terms of quantity and quality, more and more businesses are interested in setting up small and medium scale oil mills. · edible oil refining is a complex process that requires specialized equipment to ensure impurities are removed and oil quality is improved. from degumming tanks to deodorizing towers, each piece of equipment plays a vital role in producing safe and nutritious edible oil.