performance natural plant soybean oil refined plant

performance natural plant soybean oil refined plant

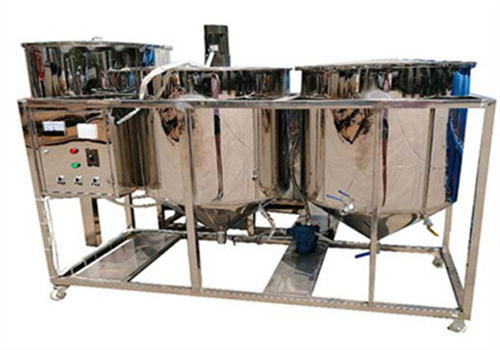

| Product Name | soybean oil refining machine |

| Weight | 680kg |

| Processing Capacity | 500kg/h |

| Power | 5.5kw |

| Voltage | 220V |

| Overall dimensions | 1800*1200*1500mm |

| Features | High Efficiency |

| Advantage | best maufacturer |

| Transport Package | Container |

| After-sales Service | Video technical support, Online support |

| Custom Service | Provide |

improve soybean yield and oil productivity

vegetable oil refining equipment can remove gums, pigments, waxes, phospholipids and free fatty acids, some of which are harmful to our health. recent studies have shown that applying compost to soybean fields can significantly improve nutrient utilization, promote crop growth and yield. phosphorus is an important nutrient that plays a vital role in root development, plant maturity and disease resistance.

small overview of soybean oil production line edible oil press,nov 07, 2018 · the soybean oil production line is a process of processing soybeans by pressing or leaching to obtain more crude oil, and then refining to obtain edible refined oil. pressed soybean oil has natural color, aroma and taste, and retains various nutrients of the raw material compared to leached oil.

the impact of refining processes and the use of natural antioxidants on soybean oil

studies on neutralizing soybean oil with sodium silicate have shown that both yield and quality have been improved, and soaps and trace metals have been effectively removed. this allows for efficient

big overview of soybean oil production plant,december 9, 2019 · large-scale soybean oil production plants involve several interrelated processes to effectively extract oil from soybeans and produce high-quality refined soybean oil. the soybean oil production line includes soybean pretreatment process, soybean pre-pressing process, soybean oil extraction process, soybean crude oil refining process and other processes.

soybean oil process pmc profitability analysis

in the profitability analysis of the soybean oil extraction process, the total capital investment of the three processes of extrusion process, hexane extraction, and eaep is us$26.6 million, us$41 million, and us$7.6 million (2015 prices), respectively, calculated based on an annual output of 30.8 million kg, 22.4 million kg, and 1 million kg of soybean oil.

high quality possibilities of producing energy, fuels and chemicals from soybeans,soybean processing plants produce refined oil, soy protein concentrate and soy protein isolate, which produce residues that may produce new products with commercial value if subjected to additional industrial operations.

expert guide to the secrets of soybean oil refining process

soybean oil refining is a process to remove impurities and improve its stability, and is a key step to ensure the excellent quality of oil products. as the demand for soybean oil from various industries has been steadily increasing, the market for soybean oil and its refined products is expected to grow further.

soybean refinery – process modeling and techno-economics,february 18, 2023 · this is the readme file of the superpro designer example, which analyzes a soybean refinery, including two superpro models (case a and b). case a simulates a typical soybean crushing plant that…

soybean oil production line, soybean oil extraction plant project

april 29, 2018 · soybean oil production line is the process of processing soybeans by pressing or leaching to obtain more crude oil, which is then refined to obtain edible refined oil. pressed soybean oil has natural color, aroma and flavor, and retains various nutrients of the raw material compared to leached oil.

advantages of refining u.s. soybean oil,degumming of crude oil for refining soybean oil buyers of soybean oil should consider the compositional differences between soybean oils from different sources. the composition of the oil can significantly affect the refining process, including the yield of refined oil and the cost of refining.

soybean oil refining machiney

we are a leading manufacturer and exporter of soybean oil refining machiney systems for processing crude oil into refined soybean oil. refining technology means separating impurities from the oil to improve the oil’s stability and purity.

soybean oil refiningdoc-developpement-durable.org,several processes can be used to produce edible oil. we will deal primarily with the alkali refining process, which is the most widely used and probably the most reliable process for producing high-quality oil.

what are the components of a soybean oil refining machiney?

with the growing demand for the quantity and quality of edible oils, more and more businesses are interested in setting up small and medium-sized oil mills. · a soybean oil refining machiney is designed to remove impurities and improve the stability of soybean oil. the components of a soybean oil refining machiney include degumming, deacidification, decolorization, and deodorization.

how is soybean oil made? the actual manufacturing process,sep 26, 2024 · the soybean oil production process involves several key steps that transform the raw soybeans into the refined oil commonly used in cooking, food, and industrial applications. here is a detailed description of how soybean oil is made:

soybean oil quality fact sheet refining u.s. soybeans delivered

crude degummed soybean oil (cdsbo) must be refined to produce high-quality soybean oil suitable for human consumption and many industrial uses. the traditional method of refining cdsbo is called alkali refining.

quality characteristics of different types and different soybean oils,wang et al. [35] showed that after water degumming and deacidification with 3% magnesol adsorption and soft deodorization at 150°c for 1…

refining to us soybean specifications

jan 16, 2018 · a: crude soybean oil can be produced to customer specifications in several steps. in the early refining stage, degumming removes heat-labile phospholipids that can darken the oil.

study on evaluation of frying performance of refined soybean oil,in this study, we evaluated the frying performance of plc degummed refined soybean oil, focusing on ffa, pv, tpc, polymer content, color, and foaming value in chicken wing and potato chip tests.

biofertilizers with plant growth promoters – natural

march 11, 2025 · sulfur application promotes accumulation of soybean (glycine max) plant dry matter, increases thousand kernel weight and yield 24. plant growth, performance and yield

soybean oil demand soars chs inc.,february 27, 2023 · in preparation for the 2021 harvest season, chs completed a $100 million renovation of its fairmont, minnesota soybean processing plant, which produces crude soybean oil, expanding annual crushing capacity by 30%.