vietnam energy saving peanut 20 tons oil processing plant

vietnam energy saving peanut 20 tons oil processing plant

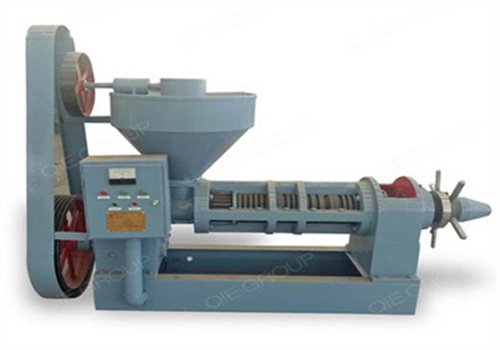

| Voltage | 380V/50HZ/3 phase |

| Type | peanut oil production line |

| Color | blue, gren ,grey or customizable |

| Weight | 920kg |

| Processing Capacity | 1-20 t/d |

| Overall dimensions | 1920x550x765mm |

| Power | 22kw/380v |

| Advantage | Long service life |

| Usage | Edible Oil |

| After-sales Service | 7*24 Hours Online Service |

| Machinery test report | provided |

energy and environment clean industry in vietnam

energy efficiency and energy saving potential in vietnam

energy efficiency and energy saving potential in vietnam is great, especially in the industrial sector, where 20-30% of energy can be saved if modern technology is applied.

top quality vietnam industry energy conservation is estimated to be about 20-30%,the peanut/groundnut oil extraction line we designed adopts durable stainless steel fixed grid plates and adds horizontal grid plates. this advanced design prevents the mixed liquid from flowing back to the discharge box and ensures high-quality crude oil extraction. according to calculations by the vietnam electricity authority, there are 3,068 key energy facilities across the country with an energy consumption of 1,000 tons of oil equivalent, equivalent to more than 6 million kwh of electricity per year.

energy-saving peanut oil production line in vietnam

the cold pressing process of peanut oil extraction machine involves several stages, including peanut shelling, peanut cleaning, peanut roasting and peanut pressing. the prime minister’s small government issued directive no. 20/ct-ttg (directive no. 20) on strengthening electricity conservation during the period 2020-2025, in which the country must strive to save at least 2.0% of total electricity consumption per year. to this end, the main

factory supply 10-20t/d edible oil production line, edible oil processing plant,one of the main uses of peanuts is oil pressing, which is the main way to consume peanuts at present. applicable to peanuts, sunflower seeds, soybeans, sesame, palm kernels, copra and other oilseeds. 2. high oil yield and less residue. 3. low investment and energy saving. 4. highly automated machines save time and labor. 5. all machines can be customized according to your requirements. 1. oilseed screw conveyor.

peanut oil refinery 5 years of efficiency and safety

the investment in the construction of the nguyen tan dung refinery enables us to produce crude oil domestically, gradually ensure energy security, reduce dependence on foreign oil supplies, and create a new look in the process of developing the central region, especially quang ngai province.

best price vietnam oil production line in 2025 manufacturer,we provide customized services to our customers, including cold pressed peanut oil, fragrant peanut oil and strong fragrant peanut oil production lines. these petroleum products play a core role in vietnam’s energy supply chain, supporting industrial development, transportation and household energy needs. the diversification of the industry into oil refining and petrochemical production further strengthens vietnam’s energy independence and economic growth.

vietnam oil expeller energy efficiency approach

mar 10, 2021 · optimizing production operations and energy conservation are important solutions to improve production efficiency and competitiveness of oil processing plants. can you give the key points for efficient use of energy in future oil processing plants?

best selling vietnam’s oil processing industry oil production line,in vietnam, the petrochemical refining industry began in 1982, when there were simple small-scale refineries such as cat lai refinery and processing plant (belonging to saigonpetro), phu my (belonging to petrovietnam), can tho (invested by thai company rpc and then transferred to vietnamese investors) and individual petrochemical plants such as 2 pvc plants, peanuts must first be pre-processed by professional seed cleaning equipment, and the cleaned peanut seeds will be sent to the oil mill, and then pressed into oil by the oil press. however, crude peanut oil usually contains many impurities, so for edible oil, the pressed peanut oil needs to be extracted in the leaching plant first, and then the extracted oil is sent to the refinery for further processing.

high quality peanut oil press machine challenges suppliers

oil demand has reached a stable level, peaked in 2019, and will not increase further. natural gas/lng will surpass oil as the largest primary energy source in 2026. it will peak in 2035 and then gradually decrease until 2050.

large scale vietnam national reporteria,aps2: improve the energy efficiency of thermal power plants. by 2050, the efficiency of coal- and residual oil-fueled thermal power plants is expected to increase to 42% and 37%, respectively, compared with 37% and 35% in the infrastructure period, while the efficiency of natural gas using combined cycle gas turbine technology will increase from 53% in the infrastructure period to 58% in 2050.

approval of peanut oil processing plant vietnam energy online

jul 20, 2023 · develop infrastructure for the supply of gasoline, oil and natural gas to meet oil processing plant transportation needs from suppliers (petroleum refineries, gasoline and oil terminal warehouses, lpg distribution stations and imported lng warehouses) to consumers in industrial and civil centers.

small scale vietnam’s industrial energy saving is estimated to be about 20-30%,dec 22, 2024 · according to calculations by the electricity authority of vietnam, there are 3,068 important energy facilities in the country, with an energy consumption of 1,000 tons of oil equivalent, equivalent to an annual power generation of more than 6 million kwh.

peanut oil products confirm vietnam 4-star standard

jul 23, 2023 · products that meet the province’s 2020 4-star ocops standard have contributed to helping farmers get rid of the “seasonal depreciation” situation. the value of peanuts to an shui farmers. huong started a business and established the nhan xuan oil mill. “a child was born.

This is a trusted vegetable oil machinery manufacturer, with products covering screw oil press, hydraulic cold press, mechanical oil press, solvent extractor, vegetable oil processing plant.how pyrolysis can help vietnam achieve net zero emissions,pyrolysis can help vietnam achieve its 2050 net zero emissions goal by converting agricultural and plastic waste into biochar, bio-oil and syngas. these byproducts can reduce emissions, improve soil fertility and provide renewable energy.

national energy master plan 2021-2030, the vision is to export

energy saving of about 8 to 10% by 2030 and about 15 to 20% by 2050. greenhouse gas emissions are about. 399.449 million tons in 2030 and about 101 million tons in 2050.

this oil press can be widely used in the extraction of various oil seeds such as soybean, peanut, sunflower seed, cotton seed, sesame, rapeseed, flax seed, moringa seed, pumpkin seed, linseed, grape seed, etc.technip energyes passes vietnam petrochemical plant test,technip energyes (paris:te) announced that long son petrochemicals co., ltd.’s (lsp) olefins plant on long son island, ba ria-vung tau province, vietnam, has passed final performance acceptance testing.

vietnam energy conundrum: balancing decarbonization and oil press machine

vietnam is expanding its energy strategy to balance reliability and decarbonization by investing in liquefied natural gas (lng) and reconsidering nuclear power. lng-fired power plants provide stability and can complement renewable energy, but they also expose vietnam to risks such as price volatility and geopolitical supply disruptions.

vegetable oil press refers to the process of squeezing oil from oilseeds using mechanical principles. Most oilseeds use physical pressing processes to obtain crude oil from oilseeds. Only a few oilseeds use chemical pressing processes, such as cottonseed pretreatment and pre-pressing.vietnam large oil production line costeria,in 2015, vietnam’s total primary energy supply (tpes) was 70.1 million tons of oil equivalent (mteo). coal accounted for the largest share of the country’s primary energy supply, at 35.9%; oil was second at 22.2%, followed by natural gas (13.7%), hydro (7.8%) and others (20.3%).

vietnam oil palm development oil production line

in 2008, vietnam had 35 companies processing vegetable oils in 13 provinces, with a potential capacity of 1.129 million tons of refined oil (actual capacity was 51.3% of total capacity) and 2.969 million tons of oily materials (actual capacity was 35.3%) per year, equivalent to 85,000 tons of crude vegetable oil. among them, vocarimex

the multifunctional fully automatic screw oil press adopts mesh pressing, which saves time and labor, has high oil yield, and has the characteristics of low power, pure oil quality, and one machine for multiple uses. the machine has a high degree of automation, adopts automatic temperature control pressing technology and high-pressure vacuum filtration system, and is currently a more advanced oil pressing machine on the market.breakthrough energy saving solutions in seafood processing,6 days ago · specifically, by the end of 2025, the energy consumption standard for pangasius products will be 1,050 kwh per ton, and the energy consumption standard for shrimp products will be 2,050 kwh per ton. from 2026 to 2030, these levels will be reduced to 900 kwh per ton of pangasius and 1,625 kwh per ton of shrimp. energy-saving strategies in the seafood processing industry