cameroon chemical processing palm oil refining line cotton

cameroon chemical processing palm oil refining line cotton

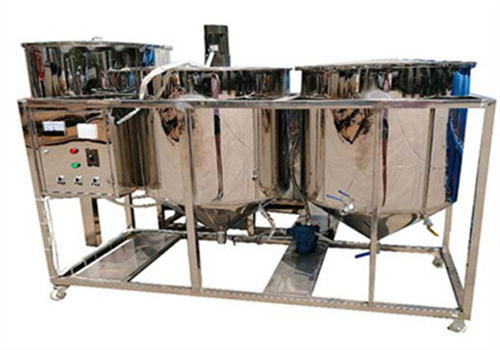

| Product Name | cottonseed oil refining machine |

| Weight | 9160kg |

| Processing Capacity | 12 ton per day |

| Power | 15-18.5kw |

| Voltage | 380V/220V |

| Overall dimensions | 2000*1210*1700mm |

| Transport package | 3X40hq container or customized |

| Advantage | best maufacturer |

| Specification | SGS, BV, ISO |

| After-sales Service | Video technical support |

| Main Market | Congo, Cameroon, Nigeria, Malawi, Uganda |

cameroon welcomes innovative palm oil refining machineies

aug 30, 2023 · cameroon’s oil sector becomes a vibrant hub of innovation and progress with the unveiling of four pioneering palm oil refining machineies. new entrants include société de raffinage du cameroun (sorac) and nouvelle raffinerie du cameroun – names that signal a new era of collaboration and growth.

small new technology palm oil production process ce approved in cameroon,cameroon oil palm expansion: sustainability insights today, oil palm cultivation and processing in cameroon involves various scales of production. henceforth, we refer to plants owned and operated by agro-industrial companies as industrial plants.

palm oil refining machineies: four new operators on the horizon

aug 29, 2023 · (business in cameroon) four new palm oil refining machineies are set to enter the cameroon market in the coming months, according to sources within the association of oilseed refiners (asroc). these newcomers include société de raffinage du cameroun (sorac) and nouvelle raffinerie du cameroun.

big cameroon’s palm oil processing industry now has new refineries,june 22, 2015 · (cameroon business) raffinerie pacific is a new palm oil refining machiney that recently opened in cameroon with an initial capital of cfa 100 million. the company will be engaged in the processing and marketing of palm oil and the manufacturing of other by-products such as margarine, candles, hand/body lotions and soaps.

edible oil mill processing equipment available in cameroon

february 6, 2021 · (cameroon business) the ministry of agriculture and rural development recently issued an international tender to select the company that will provide it with three palm oil extraction plants and a small power plant.

high quality cameroon to increase palm oil production by 26% in three years,cameroon, africa’s third-largest palm oil producer, plans to start using high-yield seeds to help boost production by 26% in the next three years. the new seeds will be planted on an additional 30,000 hectares (74,141 acres) of land, with annual production expected to increase from 230,000 tons now to 290,000 metric tons.

palm oil processing equipment and cost in cameroon

palm oil production process: a step-by-step guide. purpose: palm oil; type: palm oil manufacturing equipment; production capacity: 2-25 kg; voltage: 220v/380v; dimensions (l*w*h): 1400*860*1260 mm; weight: 280 kg; warranty: 1 year, 12 months; main selling point: sustainable; mechanical test report: provided; video factory inspection: provided

cameroon palm oil refining machiney page 2 of 4 supply,cameroon pko refiner palm kernel crude oil. use: you can extract all seeds like sesame, black cumin, hazelnut, etc… type: oil press; production capacity: 100 kg per hour; voltage: 220/240v; dimensions (l*w*h): 78*38*66; weight: 45 kg; warranty: 2 years; core components: motor, others, gears, bearings, engine, gearbox

cameroon edible oil refining fresh palm oil mill

a comprehensive guide to the edible oil refining process. application: refinery; type: edible oil refining machine; automatic level: automatic; production capacity: 45 units per year; voltage: 380v/440v; power (w): 30kw; dimensions (l*w*h): 1200*2800*1200mm; weight: 500ton; certification: ce/iso9001/bv; application: crude oil refining equipment; petroleum

the road to sustainable palm oil production in cameroon,in advocating for agro-industries, socapalm and safacam, subsidiaries of the socfin group, are responsible for more than 50% of palm oil production in cameroon and are seeking rspo certification from the roundtable on sustainable palm oil.

crude oil refining machine for cotton processing in cameroon

palm oil production process: a step-by-step guide. refining: crude palm oil is then refined to remove impurities and improve the overall quality of the oil. the process involves several stages including degumming, neutralization, bleaching, and deodorization.

palm kernel oil mills in cameroon,cdc produces an average of 18,000 to 19,000 tonnes of low free fatty acid palm oil and around 600 tonnes of palm kernel oil per year from its three mills in mondoni, idenau and illoani. all palm oil is sold locally in three packaging units (1l bottles, 5l cans and 20l cans).

palm oil production in cameroonarcgis storymaps

dec 24, 2023 · cameroun vert sarl (camvert) is owned by aboukabar al fatih, a logger with close ties to cameroon’s ruling party. camvert manages the largest monoculture palm oil plantation in central africa (50,000 hectares of forest) and produces around 180,000 tonnes of palm oil per year.

cameroon’s local palm oil production falls as imports soar,in the past seven years, cameroon’s palm oil imports have increased from 96,000 tonnes in 2017 to 225,000 tonnes in 2024, according to the cameroon oilseed refiners association (asroc).

refined palm oilagrofy cameroon

apr 15, 2016 · refining process: rbd process: refining, bleaching and deodorization (rbd) palm oil undergoes three refining stages:refining: removes free fatty acids (ffa) and impurities.bleaching: removes pigments and impurities.deodorization: removes odours and flavours through steam distillation.

improving yield and quality: cameroon international,december 10, 2023 · the interprofessional committee of palm oil producers in cameroon, better known by its french acronym interpalm-cam, was launched. the main objective of the newly created entity is to improve the quality and quantity of palm oil production in the country, it was announced at a press conference held in yaoundé on december 5.

palm oil production in the chemical industry krohne cameroon

august 3, 2024 · process details. palm oil production chain; continuous neutralization in palm oil production; fatty acid methyl esters in palm oil production; fatty acid separation in palm oil production; distillation in the chemical industry

artisanal grinding of palm oil in cameroon,the study was carried out in the three main palm oil basins of cameroon, located around the oil palm agro-industrial areas of etheka, lobé and dibombari, in the central, southwestern and coastal regions of the republic of cameroon. these areas meet the biophysical conditions required for the growth and development of oil palm.

the road to sustainable palm oil production in cameroon

edible oil refining equipment mainly consists of hot water alkali tanks, oil injection pumps, refining tanks, decolorizing tanks, white casseroles, gas separators, deodorizing tanks, refined oil pumps, deodorizing tanks, vacuum pumps, observation corridors, etc. in advocacy of agro-industries, socfin group’s subsidiaries socapalm and safacam are responsible for more than 50% of palm oil production in cameroon and are seeking rspo certification from the roundtable on sustainable palm oil.

palm oil production chainpalm oil production krohne,instrumentation for multiple process steps including extraction, refining and fractionation